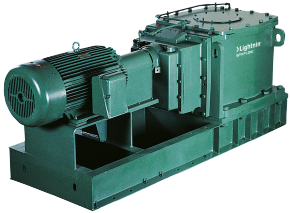

Top-entry mixers are mixing devices used across various industries for diverse mixing processes. These mixers are designed to blend large volumes of liquid in tanks and vessels. A top-entry mixer has a motor mounted on top of the mixing vessel, which drives a shaft extending into the tank. The shaft is connected to an impeller plate that generates fluid flow, promoting mixture blending. Top-entry mixers are used in industries such as pharmaceuticals, food and beverages, and chemicals. This type of mixer has become a choice for many companies worldwide to increase productivity and accelerate the mixing process. AxFlow offers top-entry mixers for a wide range of industries and applications, providing tailored advice from experienced process engineers and a selection from the world's leading process technology manufacturers, regardless of the brand.

Top Entry Mixers

7 series from 1 manufacturers

-

- Agriculture

- Aviation

- Bakery and confectionery

- Beauty & Personal Care

- Brewing and beverages

- Building Services

- Ceramics

- Chemical

- Convenience food

- Dairy

- Detergents

- Docks

- Fish Farming

- Flood Defence

- Food & Beverage

- Gas terminals

- Heating, Water & Sanitation

- Marine

- Mining

- Nuclear Power Plants

- Offshore

- Oil & Gas

- Oil Fats & Mayonnaise

- Paint & Surface Coating

- Paper Mills

- Petrochemical

- Pharmaceutical

- Power Generation

- Refineries

- Research & Development

- Surface Finishing

- Transportation

- Water Treatment

-

- Analysis

- Circulation

- Cleaning

- Control

- Conveying

- Cooling

- Descaling

- Desinfection

- Dewatering

- Diagnostic

- Discharge

- Distribution

- Dosing

- Drain

- Drainage

- Dredging

- Dual Dispensing

- Extraction

- Feed

- Filling

- Filtration

- Flow Control

- Greasing

- Grinding

- Handling

- Heating

- High-Pressure

- High-Temperature

- High-Volume

- Injection

- Irrigation

- Level Control

- Lift

- Lifting

- Loading

- Low-Pressure

- Lubrication

- Medium-Pressure

- Metering

- Mixing

- Off-loading

- Powder Coating

- Pressurisation

- Process

- Processing

- Recirculation

- Recovery

- Refueling

- Replacement

- Rinsing

- Sampling

- Settling

- Spraying

- Tempering

- Transfer

- Treatment

- Ultra High-Pressure

- Unloading

- Volumetric Dispensing

- Washing

- Water-Jet Cleaning

- Water-Jet Cutting

-

- Abrasion Resistant

- Adjustable-Flow

- Automatic

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Containment

- Corrosion-Proof

- Electric

- Explosion-Proof

- Flange

- Heavy-Duty

- High System Pressure

- High Temperature

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- In-Line

- Intrinsically Safe

- Low Shear

- Mechanical

- Mechanical Seal

- Mixed Flow

- Mobile

- Modular

- Oil-Free

- Pulse-less

- Rotary

- Rugged

- Sanitary

- Seal-less

- SIP

- Variable Speed

- Vertical

- Vertical-Mount