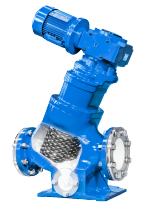

Industrial munchers are powerful and versatile machines that efficiently shred solid materials into smaller, manageable pieces. Designed for various industries, including wastewater treatment, biogas production, and industrial waste management, munchers ensure optimal performance and low energy consumption. With robust design, long lifespan, and advanced control systems, munchers minimize downtime and reduce operational costs.

Munchers and Grinders

4 series from 1 manufacturers

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Alcohols

- Ammonia

- Bitumen

- Carbon Fibers

- Caustic Solutions

- Cereals

- China Clay Slurry

- Chocolate

- CIP Fluids

- Clay

- Coffee

- Concrete

- Cooling Water

- Corrosive Dyes

- Corrosive Liquids

- Dairy Products

- Detergents

- Diesel Fuel Oil

- Drinking Water

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Ferric Chloride

- Fertilizers

- Foam Protein

- Fruit and Vegetables

- Fruit Concentrates

- Gels

- Glycol

- High Temperature Oils

- High Viscosity Liquids

- Hydrochloric Acid

- Hygienic Liquids

- Irrigation Water

- Lake Water

- Latex

- Light Fluids

- Lime

- Liquid CO2

- Low NPSH

- Low Viscosity Liquids

- LPG

- Meat

- Milk

- Molasses and Syrups

- Must

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Pet Food

- Phosphoric Acid

- Plastic

- Process Condensate

- Produced Water

- Radio Active Fluids

- Redox

- Refrigerants

- Rubber

- Sauces

- Seawater

- Separated Oil Processing

- Sewage

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Solvents

- Spirits

- Sulphuric Acids

- Surface Water

- Surfactants

- Synthetic Fibers

- Thermal Oil

- Thin Liquids

- Thixotropic Fluids

- Toluene

- Ultra Pure Water

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Wastewater

- Water

- Water Hardness

- Wine

- Wort

What is the Operating Principle of a Muncher?

An industrial muncher, also known as a grinder, operates by shredding solid materials into smaller, manageable pieces. The primary mechanism consists of two counter-rotating shafts with hardened molybdenum steel blades. These shafts can be set to rotate at different speeds, creating an optimal cutting force. The blades and spacers on the shafts vary in thickness, contributing to the effective reduction of material size. This design enables munchers to efficiently break down solid waste into smaller particles, suitable for further processing or disposal.

Advantages of Munchers

Munchers offer several significant advantages for industrial operations. One of their main strengths is their ability to efficiently break down a wide range of materials, such as textiles, branches, and fibrous waste like wipes and condoms. This versatility makes them valuable in various sectors, from wastewater treatment to biogas production. Additionally, munchers are known for their energy efficiency, consuming less power compared to other shredding solutions, which helps lower operational costs over time.

Another key advantage of munchers is their durability and long lifespan. Thanks to their robust design and high operational efficiency, they typically require minimal maintenance. In fact, many munchers can run for up to two years without needing service, although annual inspections are recommended to ensure optimal performance. Moreover, these machines are equipped with advanced control systems, such as built-in PLCs, which offer overload protection. If a blockage occurs, the muncher can automatically reverse its operation up to three times to clear the obstruction. If the blockage persists, the system will shut down, preventing damage to the motor and minimizing downtime.

However, there are also some risks associated with munchers. Despite their design for handling various materials, they can still encounter blockages, especially if non-processable items enter the system. While the built-in protection mechanisms reduce the likelihood of severe damage, persistent jamming may still require manual intervention.

Why Buy Munchers from AxFlow?

We offer a comprehensive range of industrial munchers designed to meet the needs of various industries and applications. By choosing us, you'll benefit from expert guidance provided by our highly experienced process engineers, ensuring you receive the perfect muncher tailored to your specific requirements. Our team has access to leading manufacturers and cutting-edge technology, guaranteeing that you get the best equipment available on the market.

If you're unsure which muncher best suits your needs, don't hesitate to contact us. We provide expert advice and personalized recommendations to make sure your operations run smoothly, with reduced downtime and increased productivity.