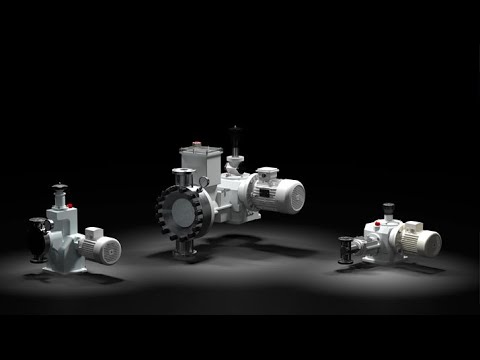

OBL Topline X9 series

SubCategory: MeteringPumps

Manufacturer: Obl

Industry: BeautyPersonalCare;Chemical;FoodBeverage;MechanicalEngineering;OilGas;Pharmaceutical

Key Specifications

- Flows up to 3700 l/h

- Pressure up to 350 bar

Product features

- Robust and efficient design

- For the toughest chemical processing applications

- Unmatched metering accuracy,

Product description

X9 series OBL metering pumps, with as STD an innovative double diaphragm construction, are specifically designed for continuous demanding Chemical, Oil & Gas and industrial applications.Extreme reliability and durability are guaranteed by the positive return mechanism (full motion) and by the mechanically actuated replenishing valve (smart diaphragm) and built-in relief valve. These pumps are supplied as STD with local visual diaphragm burst detector via pressure gauge. On demand, pressure switch and pressure transmitter for both safe and hazardous areas can be supplied. Oil-bathed seal-less ceramic plunger guarantees low NPSH r and minimum maintenance.

Modular horizontal pumps combination with different sizes and strokes per minute(each pump has its own independent internal reduction gear), for pulse-less or different injection points.X9 STD pump head material include SS316L, PVC, PVDF and PTFE. Special construction with exotic materials on demand.X9 series conform to API 675 standard, meeting its constructional,design and performances requirements:-

±1% steady state accuracy within 10% and 100% of rated capacity.

± 3% repeatability and linearity within 10% and 100% of rated capacity.

The API 675 X9 series is compliant to ATEX (94/9/CE), suitable for installation ingroup II, category 2 (zone 1/21) and group II category 3 (zone 2/22).

Operating temp up to 100 °C with metallic wetted parts,higher temperatures on demand.