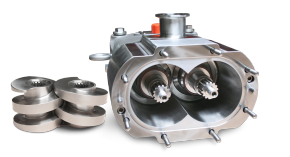

Screw pumps typically employ either two, three and for some applications up to five parallel screw spindles to transport liquids along their axis by the counter rotation of the intermeshing screws. Contained in a sealed housing, the screw spindles may be driven by external timing gears located on a drive shaft or drive shaft connected to a motor. These precision gears prevent screw contact by maintaining a constant space between the screws. This action delivers a consistent volume of fluid that is not influenced either by the viscosity or pumping pressure. They are available in single entry, double entry, horizontal and vertical configurations.

Screw Pumps

1 series from 1 manufacturers

-

- Abrasion Resistant

- Adjustable-Flow

- Automatic

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Corrosion-Proof

- Electric

- Explosion-Proof

- Flange

- Heavy-Duty

- High System Pressure

- High Temperature

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- In-Line

- Low Shear

- Low-Noise

- Mechanical

- Mechanical Seal

- Mobile

- Modular

- Pulse-less

- Rotary

- Rugged

- Sanitary

- Self-priming

- Single-Stage

- SIP

- Solids Handling

- Variable Speed

The Operating Principle of Screw Pumps

Twin, Triple, and Multi-screw pumps operate similarly and are typically self-priming, handling both low and high suction pressures across various flow rates. Twin screw pumps involve a drive and a driven idler spindle, while Triple and Multi-screw pumps use a single power rotor with idler rotors acting as rotating seals. This design ensures continuous, smooth flow that is gentle on shear-sensitive fluids. They can operate at high speeds for fast cleaning or high volume delivery, with flow rates ranging from 10m³/h to 5000m³/h, temperatures from 40°C to 150°C, and pressures up to 150bar.

Advantages of Screw Pumps

Screw pumps offer many advantages, notably in their design has better mechanical efficiency than other types of positive displacement pumps. This means that they use less power for the same capacity relative to a gear pump, thus saving energy costs. The essential factors that should be noted are:

- Robust construction

- Compact design

- Self-priming

- Work with low suction pressure

- Dry running

- Bidirectional flow

- High efficiency due to internal compression

- Constant low pulsation product flow low rotor wear

- High and low pumping speeds

- Suitable for use with variable speed drives

- Suitable for CIP cleaning Low life cycle costs

- Handle shear sensitive and viscous fluids

- Very low noise level Handle gaseous liquids

- No contamination of the medium.

Why buy screw pumps from AxFlow?

AxFlow provides screw pumps that cater to an extensive variety of industries and applications. Exclusive to AxFlow, you will be provided with personalized recommendations from highly experienced process engineers, and access to the most prominent process technology manufacturers that are independent of the manufacturer. If you require assistance in selecting the appropriate pumps that satisfy your requirements, feel free to contact AxFlow without any delay. AxFlows engineers and specialists can help with the selection process, specifications, installation, and maintenance of your fluid handling equipment.