AxFlow offer a range of products which are perfect for Lime Dosing.

The lime needs to be added in carefully measured doses so that the pH and alkalinity of the water can be sustained at the appropriate levels, influencing specific demands on the dosing pumps. Lime slurry contains high amounts of solid particles, making it difficult to pump without the correct equipment.

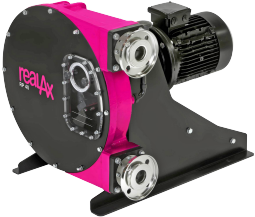

Peristaltic pumps

Peristaltic pumps are highly accurate and repeatable dosing pumps where the pumped product is completely contained within the hose. Therefore, this removes the chance that any moving parts clog or corrode; rendering peristaltic pumps the best choice for pumping high solid content slurries such as lime.

AxFlows peristaltic pump options such as our RealAx range provide a fantastic solution to pumping slurries such as lime.

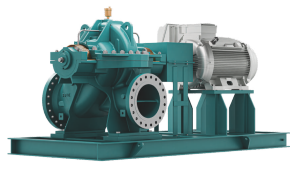

Progressive cavity pumps

Lime dosing in utility applications creates some obstacles for pumps and results in blockage, component failure, and potential leakages. The use of progressing cavity pumps, which have a longstanding tradition of managing lime slurries are an ideal solution to overcome this. Such pumps function great in strenuous environments due to their durability, low-maintenance, and corrosion resistance.

Metering pumps

Contact our specialist team who can advise you on the ideal product for your pumping application.