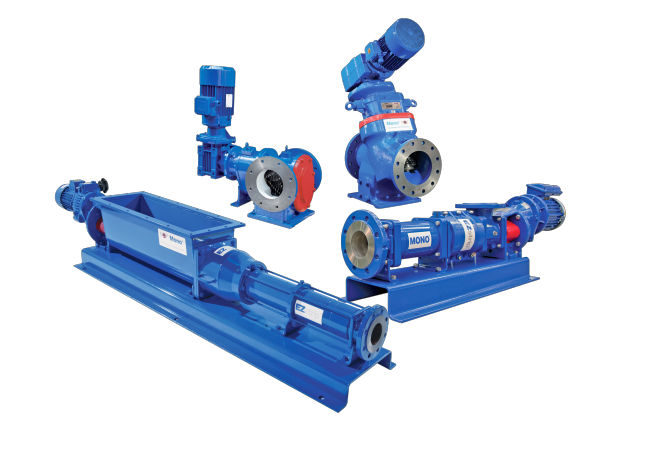

Mono EZstrip Family

SubCategory: ProgressiveCavityPumps

Manufacturer: Nov

Industry: DetergentProduction;HeatingWaterSanitation;Mining;WastewaterTreatment;WaterTreatment;BuildingServices;Ceramics;Chemical;ClayProduction;PaintResinProduction;PaintSurfaceCoating;PaperMills;SurfaceFinishing;SurfacePit;Transportation;OilGas;AcetateProduction;AdhesivesProduction;Agriculture;Petrochemical;DyePigmentProduction;FertilizerProduction

Key specifications

- Flows up to 225 m³/h

- Pressure up to 12 bar

Product features

- ‘Maintain-In-Place’ (MIP)

- Comprising a progressing cavity pump, sludge pump and grinder

Description

EZstrip™ is a family of products, patented and manufactured by NOV Mono. Launched in 2009, EZstrip™ has revolutionised the way in which progressing cavity pumps and associated products are maintained. The main feature of the EZstrip™ is the ability to ‘Maintain-In-Place’ (MIP), making a day-long maintenance operation of a PC pump into a 30 minute job. Currently comprising a progressing cavity pump, sludge pump and grinders, EZstrip™ is the biggest leap forward within the progressing cavity pump market for 30 years.

EZstrip™ Transfer Pump

This innovative progressing cavity pump has been specifically designed to provide a quick and easy way to disassemble, de-rag and maintain a progressing cavity pump in-situ in two and a half minutes! This eliminates the costly maintenance and down-time that servicing a progressing cavity pump can cause. The EZstrip™ transfer pump can be installed into new plants or retro-fitted into existing NOV Mono Compact C installations. No electrical disconnection is required and suction and discharge pipes remain untouched.

EZstrip™ Cake Pump

The sludge pump can be completely stripped down and re-built in just 15 minutes, without the need to disconnect or remove any pipe work. The sludge pump features a specifically designed feed chamber that is disconnected by removing only a few screws and allows access to the pin joint area for removal of any blockages or compressed cake. Once the rotor assembly is disconnected from the screw conveyor, the rotor and stator can be removed – all in just six minutes – remarkable by any standards! The EZstrip™ cake pump is designed with a large auger inlet and screw conveyor. The screw conveyor extends to the compression area to help push the sludge cake into the cavities of the rotor and stator and provide consistent pumping. A side inlet port also allows the addition of thin sludge for blending applications or for draining the pump. Typical applications for the EZstrip™ sludge pump include thickened sludge cake (up to 40 per cent dry solids content), de-watered sludge, lime powder coating, sludge blending and barrier layer injection.

EZstrip™ TR Muncher®

The latest addition to the EZstrip™ family is a range of grinders offering a competitive solution to solids grinding and sludge conditioning. The EZstrip™ Munchers all house the quick release access port allowing the cutter assembly to be maintained in place without removing the equipment, reducing maintenance time.