Dosing of chemical compounds in the production of silicones

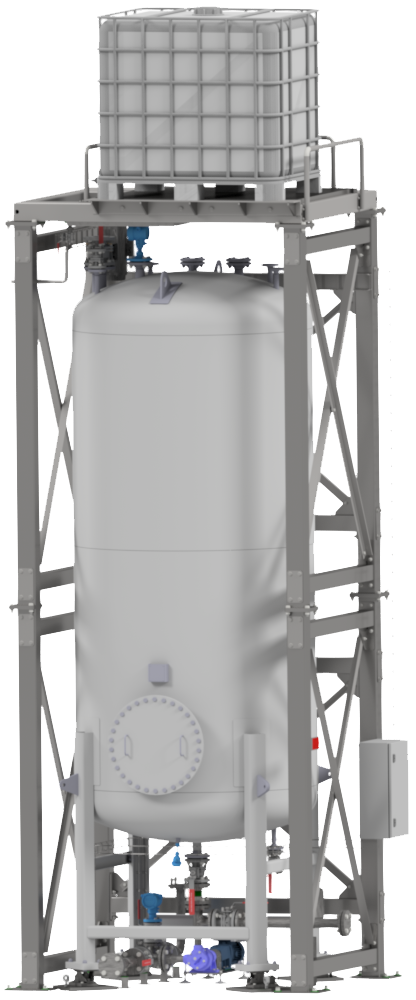

Skid unit for storage and dosing of key chemical compounds in silicon production.

The medium is delivered in 1.000 l IBC containers and stored using a pallet truck. From there, it is automatically and gravitationally filled into a buffer tank with a capacity of 5,000 litres, while the level is continuously monitored by a radar sensor. Subsequent dosing of the medium is ensured by a robust gear pump with internal gearing and integrated safety valve.

SYSTEM PARAMETERS

- Flow rate: 155 l/h

- Pressure: 5.5 bar

- Medium: Vernetzer

- Medium concentration: 100 %

- Medium temperature: 20 °C

- Viscosity: 250 cP

- Tank capacity: 5000 l

- Height: 5.3 m

- Footprint: 2.3 × 1.8 m

- Weight: 1800 kg

- Materials: Stainless steel 1.4571

Used components

Viking H724, Mettler-Toledo strain gauge scales, 5000L supply tank

Features

The drives are equipped with decentralized frequency converters with Profisafe modules. The domain of these modules is safe communication and the integration of safety stop functions (STO) directly in the inverter without the need for external safety relays.