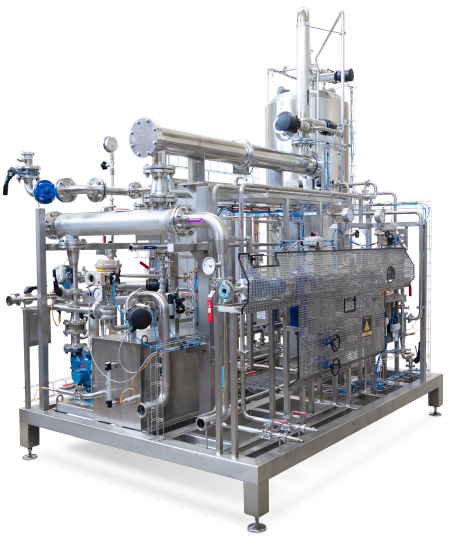

DSI unit - direct steam sterilizer

Sterilizer with direct steam injection designed for the food industry and biotechnology.

The purpose of DSI - direct steam injection technology is to sterilize biomass by direct steam injection and then homogenize the sterilized biomass in an homogenizer and transfer it into the inoculation tank. The injected water vapor is separated in a flash tank, which operates in a vacuum. The delivery included connection of all utilities at the customer's site.

SYSTEM PARAMETERS

- Flow rate: 250–500 m³/h

- Pressure: HMG 1000 bar

- Medium: biomass

- Medium concentration: 100 %

- Medium temperature: 20 / 40 / 125 / 60 °C

- Viscosity: 50 cP

- Height: 3.4 m

- Footprint: 4.3 × 2.3 m

- Weight: 1150 kg

Vacuum Parameters

- Vacuum: 300 mbar(A)

- Service fluid: water

Used Components

Waukesha priming pump, PompeTravaini Vacuum Pump, Flash Tank, SPX Homogenizer, Regenerative Tube Heat Exchanger, Plate Cooler, Steam Treatment Kit

Features

The unit is capable of continuous operation without the need for washing for 17 hours. The unit in the flash tank deairs the product very effectively, so the foamed product does not threaten the operation of the homogenizer so much and thus significantly extends the life of wear parts.