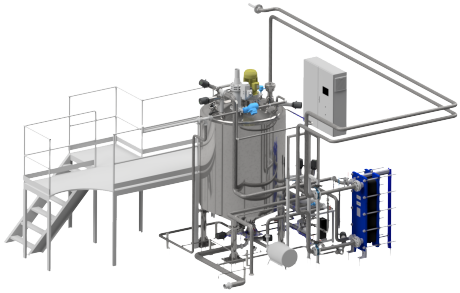

Syrup unit

System for the production, heating and automatic transferring of highly concentrated syrup.

The system automatically doses water into the 3,000 l tank. Subsequently, sugar is simultaneously added to the desired sugar content, intensive mixing is carried out using a high-shear mixer and heating is carried out via an external heat exchanger from a temperature of 20 °C to a temperature of 60 °C. After the solution is produced, the system automatically transfers the volume of the tank into the technology for further processing.

System Parameters

- Flow rate: 28 m³/h

- Pressure: 5 bar

- Medium: Syrup

- Medium concentration: 55 Brix

- Medium temperature: 60 °C

- Viscosity: 50 cP

- Tank capacity: 3000 l

- Height: 3 m

- Materials: SS 1.4301

- Certifications: FDA, 3A

Features and used components

The system is capable of producing one batch containing 2 tons of sugar with a sugar content of 55 Brix in 20 minutes.

APV W+ transfer centrifugal pump, APV plate heat exchanger, high-shear mixer, APV valves, filtration unit.