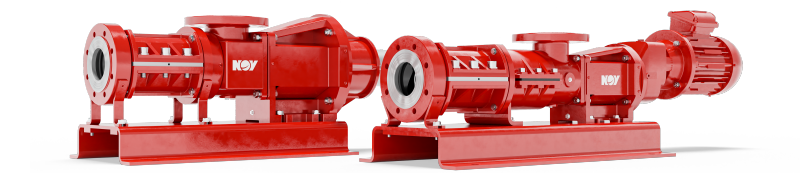

NOV Introduces the New Progressive Cavity Pumps of the Scion Product Line

At the beginning of 2026, NOV will consolidate all existing Mono series into a unified, modernized product line. The Scion progressive cavity pumps will feature a new color design and deliver enhanced performance, improved maintenance accessibility, and reduced life cycle costs. With 17 model variants each, the Scion series will cover a broad flow range across all pressure stages.

The New Series: Scion EZstrip and Scion 2000

The new Scion product line includes two series based on the proven Mono EZstrip and Mono 2000 technologies. Both are available in single- and two-stage configurations, deliver flow rates of up to 410 m³/h, and achieve differential pressures of 6 or 12 bar.

The two series differ primarily in their power transmission components and maintenance features. The NOV Scion EZstrip series is equipped with a classic coupling rod and pin joints, allowing for complete maintenance in situ. In contrast, the NOV Scion 2000 series uses gear joints designed to absorb and compensate for sudden load peaks during the pumping process.

The first Scion models will be available as early as February 2026, with the two-stage versions being added by the end of the year. Until then, the corresponding Mono progressive cavity pumps will remain available.

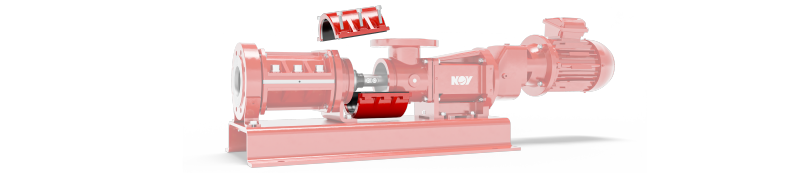

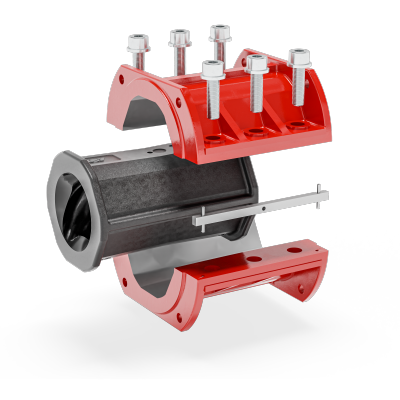

Scion EZstrip: Split housing for maintenance in installed condition

Improved Performance with Shorter Overall Length

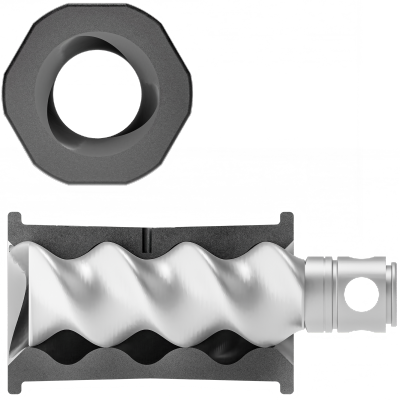

All new Scion models feature a 2:3 rotor-stator geometry to enhance performance. The larger pitch and depth enable high-pressure capabilities at low torque, while further reducing the inherently low pulsation of progressive cavity pumps.

All new Scion models feature a 2:3 rotor-stator geometry to enhance performance. The larger pitch and depth enable high-pressure capabilities at low torque, while further reducing the inherently low pulsation of progressive cavity pumps.

The optimized geometry also shortens the rotor and stator length. This significantly reduces the overall footprint of the Scion models without compromising performance or ease of maintenance—making integration into new systems or replacement of existing pumps simpler and more efficient.

Removable Stator Core Reduces Maintenance Effort and Costs

Unlike previous models, NOV now uses a removable stator core that is no longer vulcanized into a metallic outer shell. Instead, the static component is user-friendly and inserted into a split housing section in front of the discharge port. Compared to previous designs, the weight of the new stator has been reduced by an average of 80%, making replacement significantly easier and eliminating the need for lifting equipment.

Unlike previous models, NOV now uses a removable stator core that is no longer vulcanized into a metallic outer shell. Instead, the static component is user-friendly and inserted into a split housing section in front of the discharge port. Compared to previous designs, the weight of the new stator has been reduced by an average of 80%, making replacement significantly easier and eliminating the need for lifting equipment.

The absence of an outer housing also makes the Scion stator more cost-effective in terms of spare parts. In addition, the new design enhances resource efficiency and reduces disposal costs, as the single-material elastomer can be recycled without additional separation steps.

Modularity: Simplified Spare Parts Management

To streamline spare parts procurement, NOV has developed a modular stator that can be used in both single- and two-stage pump designs. In high-pressure applications, two identical stators are simply positioned in sequence to achieve pressure stages of up to 12 bar.

Depending on wear, the stators can be replaced individually. This is especially beneficial in applications where varying pressure levels or abrasive media lead to uneven wear.

Pumps, Spare Parts and Service BY AxFlow

As with the Mono progressive cavity pumps, AxFlow will also exclusively handle specification, spare parts supply, and service for the new NOV Scion series in Germany and Switzerland. Our product management, technical sales, and service teams remain fully available to support you with all questions regarding both new and existing progressive cavity pumps. Get in touch with us today.