Plate heat exchangers work by transferring heat between two fluids that flow on opposite sides of metal plates. The hot and cold fluids pass through separate channels, with the plates acting as the interface for heat exchange. The corrugated design of the plates enhances turbulence, increasing heat transfer efficiency. The fluids can flow in either counter-current or parallel arrangements, but counter-current flow is more efficient as it maximizes the temperature difference. Gaskets between the plates prevent fluid mixing, and by controlling the flow rates, the heat transfer rate and temperature difference can be adjusted. The compact design and large surface area of the plates make plate heat exchangers efficient and widely used in various industries.

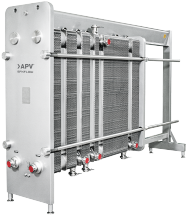

Plate Heat Exchangers

1 series from 1 manufacturers

-

- Analysis

- Booster

- Circulation

- Cleaning

- Control

- Conveying

- Cooling

- Descaling

- Desinfection

- Dewatering

- Diagnostic

- Discharge

- Distribution

- Drain

- Drainage

- Dual Dispensing

- Feed

- Filling

- Filtration

- Flow Control

- Greasing

- Grinding

- Handling

- Heating

- High-Pressure

- High-Temperature

- High-Volume

- Irrigation

- Level Control

- Lift

- Lifting

- Loading

- Low-Pressure

- Lubrication

- Medium-Pressure

- Process

- Processing

- Recirculation

- Recovery

- Settling

- Tempering

- Treatment

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Alcohols

- Ammonia

- Beer

- Bitumen

- Carbon Fibers

- Caustic Solutions

- Cereals

- China Clay Slurry

- Chocolate

- CIP Fluids

- Clay

- Coffee

- Concrete

- Cooling Water

- Corrosive Dyes

- Corrosive Liquids

- Dairy Products

- Detergents

- Diesel Fuel Oil

- Drinking Water

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Ferric Chloride

- Fertilizers

- Foam Protein

- Fruit and Vegetables

- Fruit Concentrates

- Gels

- Glycol

- High Temperature Oils

- HydrochloricAcid

- Hygienic Liquids

- Irrigation Water

- Lake Water

- Latex

- Light Fluids

- Lime

- Liquid CO2

- Low NPSH

- Low Viscosity Liquids

- LPG

- Meat

- Milk

- Molasses and Syrups

- Must

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Pet Food

- Phosphoric Acid

- Plastic

- Process Condensate

- Produced Water

- Radio Active Fluids

- Redox

- Refrigerants

- Rubber

- Sauces

- Seawater

- Separated Oil Processing

- Sewage

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Solvents

- Spirits

- Sulphuric Acids

- Surface Water

- Surfactants

- Synthetic Fibers

- Thermal Oil

- Thin Liquids

- Thixotropic Fluids

- Toluene

- Ultra Pure Water

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Wastewater

- Water

- Water Hardness

- Wine

- Wort

WHY BUY PLATE HEAT EXCHAnGERS FROM AXFLOW

AxFlow supply APV plate heat exchangers, APV plate heat exchangers are designed with advanced technology and optimized plate patterns to maximize heat transfer efficiency. As well as this, APV Plate heat exchangers are available in various plate types, sizes and configurations, thus making them highly versatile and suitable for a range of applications.

WHERE CAN PLATE HEAT EXCHANGERS BE USED:

-

Chemical Processing: In various chemical processes, plate heat exchangers play a crucial role in heating, cooling, and condensing fluids, contributing to process efficiency and energy savings.

-

Food and Beverage Industry: Plate heat exchangers are used for pasteurization, heating, and cooling applications in the food and beverage production, preserving product quality and safety.

-

Marine industry: Plate heat exchangers are employed in marine vessels for various cooling and heating purposes, including engine cooling, HVAC, and desalination.

-

Oil and Gas Industry: Plate heat exchangers are used in the oil and gas sector for various processes, such as crude oil cooling, natural gas processing, and heat recovery.

-

Pharmaceutical Industry: Plate heat exchangers are utilized for heating and cooling in pharmaceutical manufacturing processes, where precise temperature control is critical.

Plate heat exchangers

Plate heat exchangers work based on the principle of heat transfer through a series of thin metal plates that create a series of channels through which hot and cold fluids flow. They offer numerous advantages over other types of heat exchangers, such as high efficiency, compact size, flexible design, easy maintenance, reduced fouling, energy savings, and versatility. They are widely used in various industries and applications, including HVAC, food, and beverage, chemical, oil and gas, pharmaceutical, power generation, and marine industries. When selecting a plate heat exchanger, important considerations include heat transfer requirements, fluid compatibility, plate design, cleaning and maintenance requirements, and energy efficiency. AxFlow offers plate heat exchangers for a wide range of industries and applications and provides individual advice from industry-experienced process engineers.

How do plate heat exchangers work?

Plate heat exchangers operate based on the principle of heat transfer through a series of thin metal plates. These exchangers consist of multiple plates, which are arranged in a way that creates a series of channels through which hot and cold fluids flow. The hot and cold fluids are separated by the plates, which have a large surface area that allows for efficient heat transfer between the two fluids.

The hot fluid flows through one set of channels, while the cold fluid flows through another set of channels, running parallel to the hot fluid channels. As the fluids flow through the channels, heat is transferred from the hot fluid to the cold fluid through the thin metal plates, resulting in a temperature exchange. The fluid streams are typically counter-flowing, which allows for the most efficient heat transfer.

Advantages of plate heat exchangers

Plate heat exchangers offer numerous advantages over other types of heat exchangers, making them a popular choice for various industrial and commercial applications. Some of the advantages include:

- High efficiency: Plate heat exchangers have a large surface area which enables them to transfer heat more efficiently compared to other types of heat exchangers.

- Compact size: Plate heat exchangers are compact in size and can fit into tight spaces, making them ideal for applications where space is limited.

- Flexible design: The modular design of plate heat exchangers allows for easy customization to fit specific application requirements.

- Easy maintenance: Plate heat exchangers have fewer parts and are easy to disassemble and clean, reducing maintenance time and costs.

- Reduced fouling: The smooth surface of the plates minimizes fouling and reduces the need for cleaning, resulting in longer service life.

- Versatility: Plate heat exchangers can handle a wide range of fluids and can operate under high temperatures and pressures, making them suitable for various industrial applications.

Important considerations when selecting plate heat exchangers

When selecting a plate heat exchanger, there are several important considerations to keep in mind:

- Heat transfer requirements: The heat transfer requirements of the application will determine the size and design of the plate heat exchanger needed. Consider factors such as flow rate, temperature, and pressure to ensure the heat exchanger can meet the demands of the application.

- Fluid compatibility: It is crucial to select a plate heat exchanger made from materials that are compatible with the fluids being processed. This will help prevent corrosion, fouling, and other forms of damage.

- Plate design: The design of the plates is another important consideration. Different plate designs offer varying levels of heat transfer efficiency, pressure drop, and resistance to fouling. Consider the nature of the fluid and the operating conditions when choosing the right plate design.

- Cleaning and maintenance requirements: It is important to select a plate heat exchanger that is easy to clean and maintain. Some applications require frequent cleaning or maintenance, so choose a design that can be easily disassembled for cleaning and inspection.

- Energy efficiency: Consider the energy consumption of the plate heat exchanger and select a model that is energy efficient. This will help minimize operating costs and reduce the carbon footprint of the application.

Why buy plate heat exchangers from AxFlow

AxFlow offers plate heat exchangers for the widest range of industries and applications. Only at AxFlow do you receive individual advice from industry-experienced process engineers and the manufacturer-independent selection of the world's leading process technology. Do you need support in selecting the right pump for your needs? Do not hesitate to get in touch. AxFlows experts and engineers can provide guidance for selecting, specifying, installing, and maintaining your fluid handling equipment.