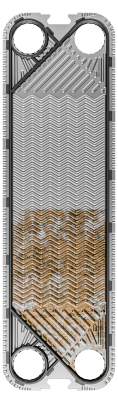

Cleaning Concept for Plate Heat Exchangers

AxFlow helps preserve the original thermal efficiency and availability of gasketed plate heat exchangers over the long term. In addition to traditional service, we offer manufacturer-independent plate cleaning, complete re-gasketing, and damage detection using fluorescent dye under UV light.

Our Services at a Glance:

-

On-site disassembly of plate packs

-

Removal of all old gaskets — clip-on or bonded

-

Chemical and mechanical cleaning of plate systems

-

Damage detection with fluorescent dye under UV light in a dedicated inspection room

-

Application or fully automated bonding of new gaskets

-

Sorting and stacking of plates according to the required sequence

-

Reassembly and subsequent pressure/leak testing

-

Spare-parts inventory with plates and gaskets from multiple manufacturers

Sustainable Reconditioning

Our reconditioning workflow is optimized for a circular, low-impact process:

-

On-site solar power supplies a significant share of the required energy

-

Treated rainwater is used for most cleaning steps

-

Material recycling routes return metals and gasket materials from damaged parts to the resource cycle

The Cleaning Process — Step by Step

Disassembly & Transport

Disassembly & Transport

Our service team removes plate packs nationwide and arranges safe transport to our facility. On request, we can also inspect the frame in our workshop.

Removal of Old Gaskets

All gasket elements are removed. Bonded gaskets are gently released using a liquid-nitrogen bath: the cryogenic medium reduces elasticity in the gasket and adhesive so they embrittle and separate cleanly from the plates.

Cleaning of Plates

Cleaning of Plates

Depending on contamination level, plates undergo mechanical and chemical cleaning stages to reliably remove production residues and fouling.

Visual & UV Inspection

After cleaning, each plate receives a thorough visual check. Any anomalies are investigated using a fluorescent dye viewed under UV light in a darkroom, making through-thickness defects clearly visible.

Re-Gasketing

Re-Gasketing

Intact plates are fitted with new gaskets. Clip-on gaskets are installed manually by our technicians. For bonded designs, a robot applies adhesive uniformly before the gasket is positioned with precision.

Reassembly & Commissioning

We reassemble the reconditioned plate pack and, on request, perform a tightness/pressure test on the complete heat exchanger prior to return or installation.

Multi-Brand Service by AxFlow

AxFlow delivers this service throughout Ireland and across all brands of gasketed plate heat exchangers. Our service operation maintains a permanent stock of replacement plates and gaskets in various sizes and materials to restore your process availability quickly.

👉 Contact our AxFlow Service team today to schedule cleaning, re-gasketing, or leak testing—and keep your plate heat exchangers performing at their best.