Comprehensive Support for AODD Pumps

As an authorized sales and service partner of Wilden Pump and Almatec, our product engineers provide application-based consultation and pump sizing. To keep your production running, AxFlow’s European central warehouse maintains pumps in multiple sizes and materials as well as all common wear components for rapid availability.

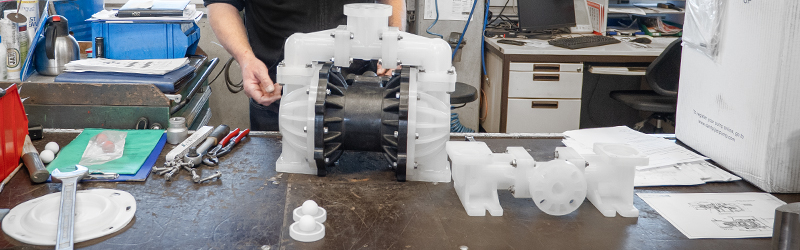

Our certified technicians handle commissioning, routine maintenance, and repairs on AODD pumps. Regular service and the use of OEM spare parts preserve efficiency and extend service life. In practice, moving and sealing components are subject to wear—often increasing air consumption and reducing overall efficiency.

Our certified technicians handle commissioning, routine maintenance, and repairs on AODD pumps. Regular service and the use of OEM spare parts preserve efficiency and extend service life. In practice, moving and sealing components are subject to wear—often increasing air consumption and reducing overall efficiency.

To further improve performance, our service team can retrofit a pulsation dampener. This protects piping and delivers a smoother, more stable flow without loss of discharge pressure.

How to Extend AODD Pump Life & Efficiency

-

Follow manufacturer-recommended maintenance intervals

-

Use OEM spare parts to maintain full functionality and compliance

-

Limit suction-side inlet pressure to protect ball valves

-

Install a soft-start valve to reduce mechanical stress at start-up

-

Prevent icing at the air valve muffler/silencer

-

Observe correct torque on all fasteners to prevent leaks

-

For abrasive media, select AODD pumps with flap valves

Service & Spare Parts — On-Site or In-Workshop

Contact AxFlow for service and spare-part requests for AODD pumps. We offer flexible support on-site at your facility or in our own workshop, tailored to your production schedules.

👉 Get in touch with our AxFlow Service team today to keep your AODD pumps running at peak performance.