Why Proactive Maintenance Matters

In modern processing, demands on valve technology for controlling and regulating liquids are constantly rising. Regular, scheduled maintenance—especially for hygienic valves—preserves efficiency, product flexibility, and continuous plant availability over the long term.

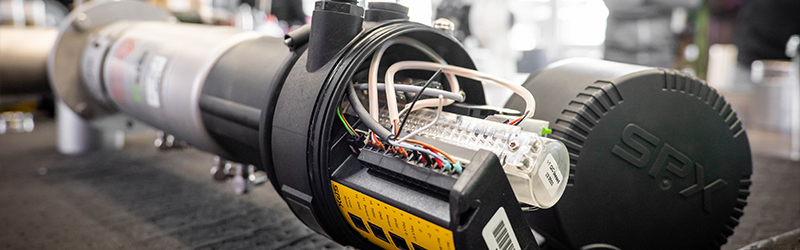

AxFlow’s Service Concept for Hygienic Valves & Manifolds

Beyond application-specific sizing and configuration, our concept also focuses on ensuring availability of critical valve technology. AxFlow’s European central warehouse stocks a wide range of valve types in different sizes and materials, plus OEM spare-part kits—ready for rapid dispatch when you need them.

Beyond application-specific sizing and configuration, our concept also focuses on ensuring availability of critical valve technology. AxFlow’s European central warehouse stocks a wide range of valve types in different sizes and materials, plus OEM spare-part kits—ready for rapid dispatch when you need them.

As an authorized APV service provider, our certified technicians handle:

-

Commissioning and operator familiarization

-

Maintenance and repairs on pneumatic actuators, valve seats, and sealing components

-

Tool-free retrofit of double-seat valves from DA3+ to the latest DA4—without welding and without replacing the valve body or connections

How to Extend Valve Life & Efficiency

-

Avoid pressure spikes to protect internal components

-

Use OEM spare parts to maintain original performance and compliance

-

Respect temperature and pressure limits to prolong seal life

-

Continuously monitor valves to detect wear and leaks early

AxFlow - Your Partner for Hygienic Valve Service

Protect uptime and product safety with AxFlow’s flexible support—on-site at your facility or in our fully equipped workshops. We provide maintenance, servicing, repairs, and efficiency improvements for hygienic valves and valve manifolds tailored to your process.

👉 Get in touch with our AxFlow Service team today to secure long-term reliability and availability.