In the 1920s, the dairy industry saw the introduction of pioneering standards aimed at enhancing the hygienic design of equipment. Dubbed the "3-A standards," these guidelines were the result of collaborative efforts among regulatory sanitarians, equipment fabricators, and processors. This collaboration was instrumental in improving equipment design and sanitation practices within the industry.

This collaboration endures through the not-for-profit entity, 3-A Sanitary Standards, Inc. (3-A SSI). Comprising the International Dairy Foods Association, Food Processing Suppliers Association, the International Association for Food Protection, and representatives from the U.S. Department of Agriculture and the U.S. Food & Drug Administration, this corporation remains dedicated to advancing food safety through meticulous equipment design.

3-A SSI maintains an extensive catalog of design criteria for equipment and processing systems. It oversees programs like the 3-A Symbol Authorization and other voluntary certificates that validate the integrity of hygienic processing equipment and systems. Additionally, it provides comprehensive knowledge resources, supporting training and education in the rapidly evolving food, beverage, and pharmaceutical industries.

Benefits of 3-A Certification

Acquiring 3-A certification for equipment offers significant advantages:

- Enhanced Hygiene: Ensures adherence to rigorous hygiene standards, promoting safe and sanitary processing.

- Credibility: Demonstrates commitment to quality and safety, fostering consumer trust and confidence.

Industry Relevance of 3-A Certification

3-A standards hold immense significance within industries like food, beverage, and pharmaceuticals:

- Regulatory Compliance: Aligns with industry regulations, ensuring products meet safety and quality standards.

- Enhanced Safety: Promotes a safer working environment by incorporating rigorous hygienic design practices.

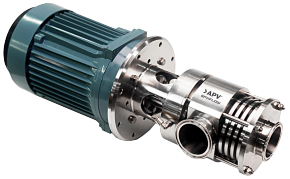

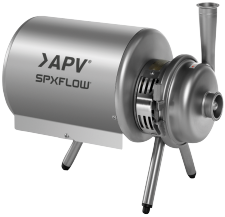

AxFlows 3-A-certified products

AxFlow prides itself on offering an extensive lineup of 3-A certified fluid handling solutions, specifically tailored to meet the exacting hygiene and safety standards within industries. Our suite of 3-A certified products, which includes pumps, valves, homogenizers, heat exchangers, and mixers, stands as a testament to our commitment to impeccable equipment design and sanitation practices. These certifications ensure that our equipment meets the stringent requirements set by regulatory bodies and industry standards.