What makes a Pump Hygienic?

Hygienic pumps are specialized pumps designed for use in industries where maintaining sanitary conditions is critical, such as food and beverage production, pharmaceuticals, and biotech. These pumps are engineered to meet the highest hygiene standards, and they are constructed using materials that are non-toxic, non-contaminating, and easy to clean. Hygienic pumps play an essential role in ensuring product purity, preventing contamination, and complying with regulatory standards.

They feature unique designs that reduce the risk of contamination by minimizing dead spaces where bacteria can accumulate. Hygienic pumps are available in a range of designs, including both centrifugal and positive displacement pumps.

One critical aspect of hygienic pumps is their ability to be cleaned and sanitized quickly and easily. Hygienic pumps are designed to be disassembled quickly, which makes cleaning and maintenance fast and efficient. This feature is essential in industries where downtime must be minimized, and production schedules are tight.

Pumps that can be configured as hygienic pumps

There are several types of pumps that are regarded as hygienic pumps due to their design and construction. Some of the most used hygienic pumps include:

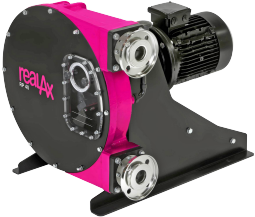

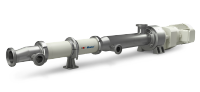

- Centrifugal pumps: These pumps are used in various industries, including food and beverage, pharmaceutical, and biotech, for transferring liquids with low to high viscosity. They work by converting rotational energy from a motor into hydrodynamic energy in the fluid, which propels it through the pump and into the process.

- Positive displacement pumps: These pumps are designed to move a fixed volume of fluid with each revolution of the pump. Examples include AODD pumps, rotary lobe pumps, peristaltic pumps, and twin-screw pumps. Positive displacement pumps are used in industries where precise flow rates are critical, such as food processing, pharmaceuticals, and cosmetics.

Advantages of hygienic pumps

Hygienic pumps offer several advantages over traditional pumps, including:

- Sanitary design: Hygienic pumps are designed to prevent bacterial growth and contamination, making them ideal for use in the food, beverage, and pharmaceutical industries.

- Easy to clean: Hygienic pumps are easy to clean and sanitize, which reduces the risk of contamination and ensures product purity.

- Cost-effective: Hygienic pumps are cost-effective in the long run as they require less maintenance and are less likely to experience downtime due to contamination.

- Versatility: Hygienic pumps can be used for a variety of applications, including the transfer of viscous and shear-sensitive products, as well as products with high solids content.

Industries and applications that use hygienic pumps

Hygienic pumps are widely used in various industries that require sanitary and sterile processing. Some of the industries and applications that use hygienic pumps include:

Food and Beverage Industry

Food and Beverage Industry

Hygienic pumps are used in food and beverage processing to transfer liquids, such as milk, juice, beer, and wine, from one point to another. These pumps are designed to meet strict hygiene and sanitation requirements, ensuring that the product is not contaminated during processing.

Pharmaceutical Industry

Pharmaceutical Industry

In the pharmaceutical industry, hygienic pumps are used to transfer liquids, such as vaccines, drugs, and other medical products. Hygienic pumps are preferred because they prevent contamination of the product and ensure that the product meets strict quality and safety standards.

Cosmetics Industry

Cosmetics Industry

Hygienic pumps are used in the cosmetics industry to transfer liquids, such as lotions, creams, and shampoos. These pumps are designed to meet the strict hygiene and safety requirements of the industry, ensuring that the product is not contaminated during processing.

Biotechnology Industry

Biotechnology Industry

In the biotechnology industry, hygienic pumps are used to transfer fluids, such as cell cultures, media, and other biologics. These pumps are designed to meet the stringent requirements for sterile processing, ensuring that the product is not contaminated during processing.

The use of hygienic pumps in these industries offers several benefits. Firstly, hygienic pumps are designed to meet strict hygiene and sanitation requirements, preventing contamination of the product. Secondly, hygienic pumps are easy to clean and maintain, reducing the risk of downtime and increasing production efficiency. Finally, hygienic pumps are designed to be energy-efficient, reducing energy consumption and operating costs.

Important considerations when selecting hygienic pumps

When selecting hygienic pumps, there are several important considerations to keep in mind. Here are a few key factors to consider:

- Material compatibility: Hygienic pumps are often used in food, beverage, and pharmaceutical applications, so it's important to ensure that the pump materials are compatible with the product being pumped. Materials such as stainless steel, titanium, and other food-grade materials are often used for this reason.

- Cleanability: Hygienic pumps must be easy to clean and sanitize to prevent contamination. Therefore, pumps with smooth surfaces, minimal crevices, and easy-to-remove parts are preferred.

- Compliance: In industries such as food and pharmaceuticals, strict regulatory standards must be followed. When selecting a hygienic pump, it's important to ensure that it meets the necessary industry standards and regulations.

Why buy hygienic pumps from AxFlow?

AxFlow provides hygienic pumps that cater to an extensive variety of industries and applications. Exclusive to AxFlow, you will be provided with personalized recommendations from highly experienced process engineers, and access to the most prominent process technology manufacturers that are independent of the manufacturer. If you require assistance in selecting the appropriate pumps that satisfy your requirements, feel free to contact AxFlow without any delay. AxFlows engineers and specialists can help with the selection process, specifications, installation, and maintenance of your fluid handling equipment.