What Makes an Circumferential Piston Pump Hygienic?

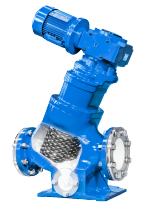

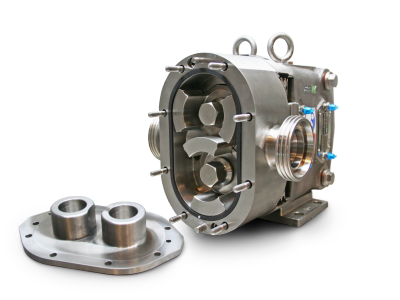

Hygienic Circumferential Piston pumps are meticulously engineered for use in hygienic applications, crafted from materials resistant to corrosion and easy to clean. Their design mitigates contamination risks, making them ideal for a diverse range of fluids, including those with high viscosity, solids, and

abrasive components. The pumps’ circumferential pistons ensure a continuous, controlled flow, with minimal pulsation—perfect for shear-sensitive or delicate fluids. Additionally, their design facilitates easy disassembly and cleaning, crucial for maintaining product purity and sanitation standards.

Key Features and Advantages:

- Precise Flow Control: Delivers consistent fluid transfer, essential for quality assurance.

- Low Shear and Minimal Pulsation: Protects delicate particles within fluids, ideal for shear-sensitive products.

- Ease of Maintenance: Simple disassembly processes support superior sanitation.

- Material Integrity: Constructed from corrosion-resistant materials to handle various challenging environments, including abrasive fluids.

- Versatility: Suitable for a wide range of applications, from high-viscosity foods to aggressive chemicals in the chemical and coatings industries.

Choosing the Right Pump: Selecting the correct ECP pump involves considering fluid characteristics, operational requirements, and compliance with hygiene standards. Factors such as fluid viscosity, shear sensitivity, and the presence of solids are critical in ensuring the pump performs effectively without compromising safety or efficiency.

Why Choose AxFlow?

AxFlow excels in providing tailored Hygienic ECP pumps, backed by expert advice, robust support, and access to leading technologies. Whether you're transferring sensitive pharmaceuticals or handling tough industrial fluids, AxFlow's solutions are engineered to meet your needs.