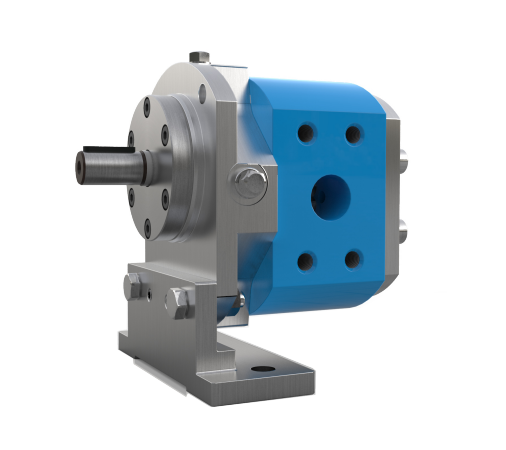

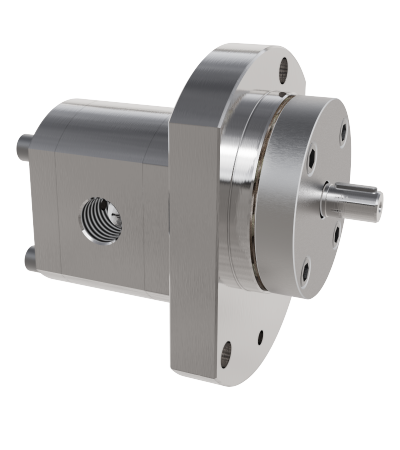

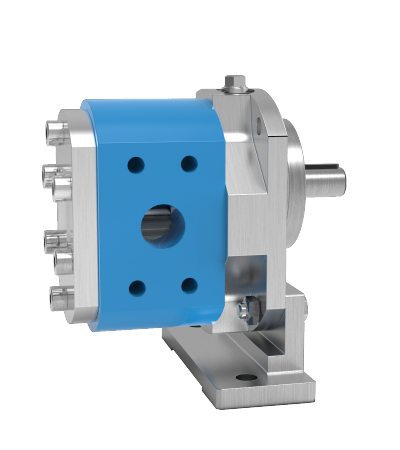

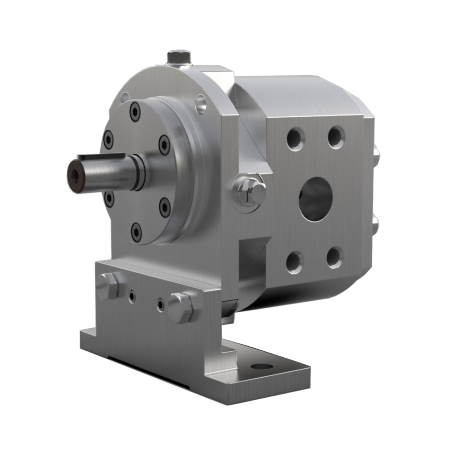

MAAG dosix™

Category: Pumps

SubCategory: ExternalGearPumps

Manufacturer: Maag

Industry:

SubCategory: ExternalGearPumps

Manufacturer: Maag

Industry:

Corrosion-resistant dosing pumps for chemical processes

Key specifications

- Pressure up to 100 bar

Product features

- Wide viscosity, temperature and pressure range

- High efficiencies due to tolerances being modified in line with applications

- Precise displacement volume

- Low pulsation

- Corrosion-resistance

- Reliability and longevity

- Safety

- Easy replacement of internal parts

- Suitable for step-motors

Description

MAAG dosing gear pumps are corrosion resistant and electrically heatable conveying units, especially designated for the small tthroughputs; their three-piece configuration facilitates maintenance and replacement of internal parts, such as gears and bearings. Thanks to the wide range of components and materials available, dosix™ pumps can be configured to suit customers specific requirements and therefore, are far superior to standard pumps in terms of performance and reliability.

Selection of typical pumped media

- Organic and inorganic chemicals

- Solvents

- Acids and alkalis

- Additives

- Cosmetic products

- Pharmaceutical products

- Food extracts and flavourings