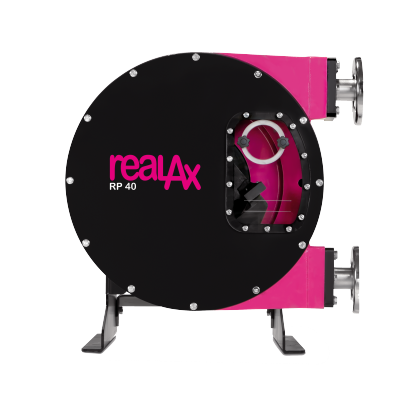

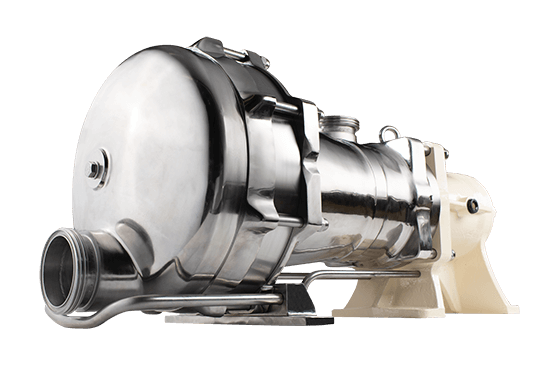

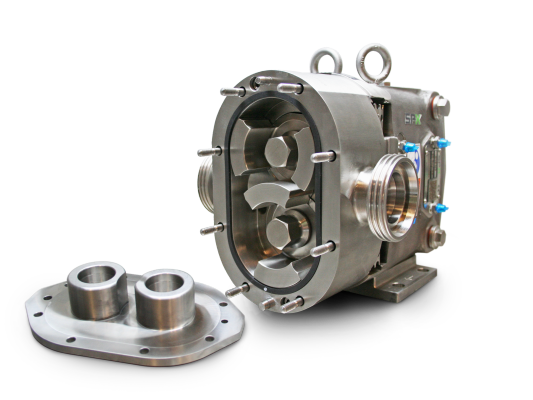

The best type of pump for sensitive and viscous fluids is normally a positive displacement pump. AxFlow are the UK's leading supplier of positive displacement pumps which will allow us to offer you the most suitable pump for the job.

Here are some of the most common sensitive and viscous liquids