Mixer Modernization & Reliability Services

Maximise the performance, reliability, and lifespan of your mixing equipment with our Mixer Modernization & Reliability (MMR) programme. Designed to proactively identify ageing or at-risk mixers, this service helps you reduce unplanned downtime, improve maintenance planning, and extend the service life of critical assets.

Through a complimentary on-site inspection, our mixing specialists evaluate the mechanical health of each mixer using over 30 data points, including vibration, noise, temperature, and a full visual inspection. This data-driven approach provides a clear picture of current condition and future risk—giving you the confidence to plan maintenance and upgrades before failures occur.

Why Modernize Your Mixers?

According to the document, the goals of the MMR programme include:

- Identifying mechanical risk factors early

- Increasing uptime and extending maintenance cycles

- Improving mean time between failures (MTBF)

- Reducing maintenance costs and emergency repairs

- Supporting strategic planning for spares and redundancy

By modernising key components and assessing operational efficiency, your plant can stay productive, compliant, and safe—without unexpected mixer failures disrupting production.

What’s Included in an MMR Assessment?

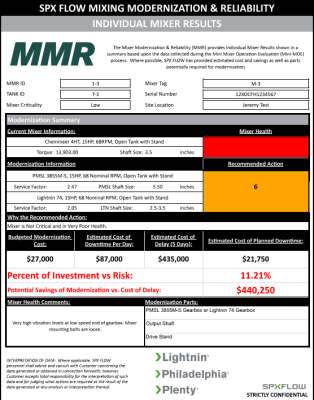

Each Mixer Modernization & Reliability report provides a comprehensive evaluation of your agitating equipment, regardless of manufacturer. As outlined in the attachment, every MMR includes:

- Audit of current equipment condition

- Visual inspections of drive, shaft, gearbox, mechanical seals, and mounting systems

- Performance evaluation, using vibration, temperature, and sound analysis

- Budgetary modernization costs for recommended upgrades

- ROI calculation, showing long-term savings potential

- Expert recommendations for modernisation and maintenance planning

This structured approach ensures you receive a practical, prioritised roadmap that supports safe and efficient mixer operation.

What You Can Expect

The MMR report clearly rates the health of each mixer and highlights where modernization can prevent breakdowns, improve reliability, and reduce operational risk. It also provides cost forecasts and projected savings—making it easy to justify upgrades and allocate maintenance budgets effectively.

With insights such as percent of investment vs. risk and potential savings, you gain a clear financial understanding of how modernization impacts long-term performance.

MS-Mixer-Modernization-and-Reli…

A Proactive Approach to Mixer Reliability

Modernization is not just about replacement—it’s about getting more value from your existing assets. By understanding mixer condition and applying targeted upgrades, plants can:

- Extend mixer lifespan

- Reduce energy usage

- Improve mixing consistency and product quality

- Avoid catastrophic failures that lead to extended downtime

Let Our Experts Support Your Plant

Whether your facility runs Lightnin, Philadelphia, Plenty or any other manufacturer’s mixers, our engineers provide unbiased, expert recommendations to keep your equipment performing at its best.

Book your complimentary inspection today and start building a safer, more reliable mixing operation.