Pumping Solutions for Corrosive Dyes

Pumping corrosive dyes demands equipment that can handle aggressive chemistry while still protecting product quality and colour consistency. Whether you’re working with concentrated liquid dyes, pigment dispersions, or dye intermediates, the pump has to cope with both corrosive attack and, in many cases, abrasive or solids-bearing media—without leaking, blocking, or breaking down.

AxFlow UK offers a choice of different product types that can both accurately meter liquids and are also chemically resistant.

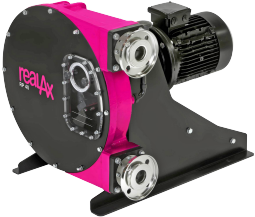

AxFlow offer APY and ISI peristaltic pumps from RealAx

Our Peristaltic pumps are ideal for pumping corrosive dyes, as there is only one internal part that encounters the fluid, the hose, and this can be manufactured in various grades of rubber to ensure corrosion resistance.

Our various diaphragm pumps manufactured by Pulsafeeder and OBL.

Our OBL & Pulsafeeder Diaphragm pumps are designed to effectively end efficiently handle corrosive materials, such as corrosive dyes in a cost effective manner.

...See our selection of recommended products below & contact our specialist team.

Typical Corrosive Dye Applications

Pumps for corrosive dyes are used in duties such as:

- Transfer from IBCs, drums, and bulk storage to day tanks or mixing vessels

- Circulation and blending of dye solutions for uniform concentration

- Feeding filters, mills, or dispersion equipment

- Dosing concentrated dyes or intermediates into process lines

- Handling wash and rinse liquors containing residual dyes and chemicals

These duties often run in batch mode with frequent colour or product changeovers.

What Operators Need

Effective pumping solutions for corrosive dyes are defined by:

- Correct wetted materials – plastics, fluoropolymers, or high-alloy metals selected for resistance to both the dye chemistry and associated acids/alkalis

- Robust sealing or seal-less designs to minimise leakage, emissions, and product loss

- Tolerance of solids and pigment particles, where dispersions or filled products are used

- Gentle, low-shear transfer to protect dispersion quality and prevent unwanted foam

- Easy cleaning and changeover to reduce contamination risk between colours or batches

- Reliable performance under variable concentration, temperature, and duty cycles

Why the Right Pump Matters

With corrosive dyes, incorrect pump choice can lead to rapid corrosion, leaks, unplanned downtime, and compromised product quality. A pump designed and specified specifically for dye chemistry and operating conditions will:

- Maintain consistent flow and colour strength

- Reduce maintenance and unscheduled stoppages

- Improve operator safety by limiting exposure and spills

- Lower total lifecycle cost through longer component life

In short, the right pump turns corrosive dye handling from a recurring problem into a controlled, dependable part of the process.