Submersible centrifugal pumps are purpose-built to operate fully or partially submerged, moving large volumes of fluid efficiently from pits, tanks, sumps, wells, and process vessels. By placing the pump directly in the liquid, submersible designs eliminate many suction-side issues associated with dry-installed pumps — delivering stable performance, compact installation, and excellent reliability in demanding environments.

Whether your application involves clean water, stormwater, industrial effluent, slurries, or corrosive liquids, selecting the right submersible centrifugal pump ensures dependable flow, reduced downtime, and lower lifecycle cost.

How Submersible centrifugal pumps Work

A submersible centrifugal pump uses a rotating impeller to impart velocity to the fluid, which is then converted to pressure (head) in the volute or diffuser. The motor and hydraulic end are sealed in a watertight housing, allowing operation beneath the liquid level.

Because the pump is already flooded:

- Priming is not required

- Net Positive Suction Head (NPSH) issues are minimised

- Cavitation risk is reduced in many common sump and tank duties

Why buy Submersible Centrifugal Pumps from AxFlow

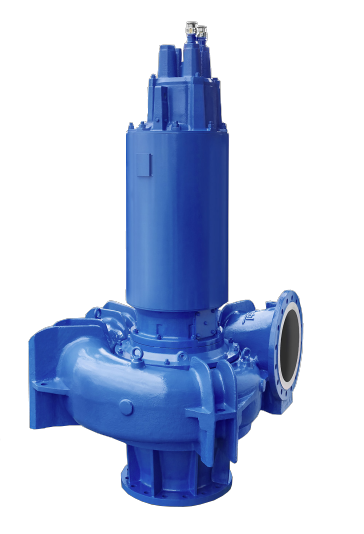

AxFlow supplies a comprehensive range of submersible centrifugal pumps from leading manufacturers including Hayward Gordon, Gruppo Aturia, and Argal, allowing us to match the right hydraulic design to each application. Hayward Gordon submersible pumps are proven in severe solids-handling and wastewater duties, with recessed, chopper, and screw/centrifugal submersible designs available for difficult media.

For high-capacity industrial and municipal services, Gruppo Aturia submersible pumps cover axial, mixed-flow and centrifugal configurations, offering robust cast iron or stainless/alloy builds for large transfer, drainage, and process water applications.

For chemically aggressive duties, Argal submersible and semi-submersible centrifugal pumps in corrosion-resistant thermoplastics (e.g., PP, PVDF) provide dependable performance in acidic, alkaline, and abrasive liquid transfer where metallic pumps are unsuitable.

Backed by AxFlow’s application engineering and service support, these ranges ensure reliable submerged pumping across clean water, effluent, and corrosive process environments.

Key Benefits of submersible centrifugal pumps

Flooded, stable suction: Operating below the liquid line provides consistent inlet conditions, improving reliability and reducing performance fluctuations.

Compact, space-saving installation: No pump house, suction pipework, or priming systems are needed. Ideal where footprint is limited.

High efficiency across wide flow ranges: Centrifugal hydraulics are well-suited to continuous transfer of low-to-moderate viscosity fluids.

Lower noise and improved safety: Submerged operation reduces airborne noise and helps contain hazardous liquids within the system boundaries.

Designed for harsh environments: Options include abrasion-resistant materials, corrosion-resistant alloys, and solids-handling impellers for challenging media.

Typical Applications

Submersible centrifugal pumps are widely used across industrial and municipal sectors, including:

- Wastewater and sewage lift stations

- Stormwater, drainage, and flood control

- Industrial sumps and pits

- Cooling water and recirculation

- Tank unloading and transfer

- Process effluent and washdown systems

- Construction dewatering

- Mining and slurry services (where suitable impellers/materials are selected)