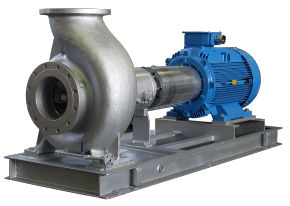

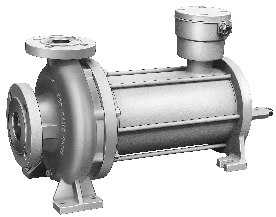

ISO 5199/2858 Pumps

AxFlow UK offers several ranges of ISO 5199 and ISO 2858 pumps.

ISO 5199 and ISO 2858 are international standards that define the design, dimensions, and performance requirements for centrifugal process pumps used in industrial and chemical applications.

These standards ensure interchangeability, reliability, and safety, allowing users to select pumps from different manufacturers with confidence that dimensions, performance, and serviceability are consistent.

Together, they form the foundation for the most common category of industrial process pumps — often referred to as “ISO process pumps.”

ISO 2858 – Dimensional Standard

ISO 2858 specifies the principal dimensions and nominal duty points for end-suction, single-stage centrifugal pumps.

This standard ensures that pumps from different manufacturers have standardized external dimensions, allowing for direct replacement or upgrade without modifying pipework or foundations.

Key Features:

-

Standardization of suction and discharge flange sizes, shaft height, and mounting dimensions.

-

Defines performance ranges (flow, head, speed) for each pump size.

-

Guarantees dimensional interchangeability across brands.

-

Applies primarily to back-pull-out design pumps — allowing easy maintenance without disconnecting pipework.

In essence, ISO 2858 governs what the pump looks like and how it fits into the system.

ISO 5199 – Design and Construction Standard

While ISO 2858 deals with dimensions, ISO 5199 specifies mechanical design and operational requirements for the same category of pumps.

It focuses on the internal engineering, robustness, and reliability needed for handling industrial fluids — including corrosive, hot, or hazardous liquids.

Key Requirements:

-

Mechanical strength and shaft design: Adequate for continuous industrial service.

-

Bearing life: Minimum of 17,500 hours at rated conditions.

-

Sealing systems: Compatibility with single, double, or cartridge mechanical seals per ISO 21049 (API 682 equivalent).

-

Material quality: Covers metallic and non-metallic materials suited for chemicals, slurries, and solvents.

-

Thermal expansion allowances and alignment tolerances for high-temperature applications.

-

Hydraulic performance verification through testing and acceptance grades.

In essence, ISO 5199 governs how the pump is built and how it performs under demanding industrial conditions.

Key Differences Between ISO 2858 and ISO 5199

| Feature | ISO 2858 | ISO 5199 |

|---|---|---|

| Scope | Dimensions and duty points | Design and construction |

| Focus | Interchangeability | Mechanical integrity and performance |

| Application | Defines suction/discharge sizes, shaft height, casing dimensions | Defines bearing life, sealing, strength, materials |

| Primary Purpose | Easy replacement and standardization | Long-term reliability and safety in process industries |

Typical Applications

ISO 5199 / 2858 pumps are widely used in:

-

Chemical and petrochemical processing

-

Water treatment and utilities

-

Oil and gas (non-API service)

-

Food, beverage, and pharmaceutical plants

-

Pulp and paper industries

-

General industrial fluid transfer

They handle fluids such as acids, alkalis, solvents, slurries, hot water, and hydrocarbons — where consistent performance, reliability, and easy maintenance are essential.

Benefits of ISO-Standard Process Pumps

-

Global interchangeability — standardized footprint and connections.

-

High reliability — robust design for continuous duty.

-

Ease of maintenance — back-pull-out design and standardized spare parts.

-

Proven engineering — compliant with international best practices for process safety.

-

Cost efficiency — long service life and reduced downtime.