Axflow is one the UK's largest suppliers of rotary lobe pumps & circumferential piston pumps

Rotary Lobe Pumps

4 series from 2 manufacturers

-

- Acids

- Adhesives

- Beer

- Biological Broths and Slurries

- Caustic Solutions

- Corrosive Liquids

- Dairy Products

- Detergents

- Emulsions

- Ferric Chloride

- Foam Protein

- Fruit Concentrates

- Gels

- HydrochloricAcid

- Latex

- Lime

- Milk

- Molasses and Syrups

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Pet Food

- Phosphoric Acid

- Rubber

- Sauces

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Silver Nitrate

- Soaps and Detergents

- Sulphuric Acids

- Surfactants

- Thixotropic Fluids

- Vegetable Oils

- Viscose

- Viscous Liquids

- Wastewater

- Wort

-

- Booster Sets

- Canned

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Containment

- Corrosion-Proof

- Electric

- Explosion-Proof

- Flange

- Heavy-Duty

- High System Pressure

- High Temperature

- High-Performance

- Horizontal Mount

- Intrinsically Safe

- Low-Noise

- Mechanical

- Mechanical Seal

- Pulse-less

- Rotary

- Seal-less

- Semi Submersible

- Single-Stage

- Submersible

- Variable Speed

- Vertical

- Vertical-Mount

Rotary lobe pumps are positive displacement pumps that create moving cavities between the synchronised lobes in the pump chamber that move the fluid around the pump chamber. Rotary lobe pumps are one of the most useful types of positive displacement pumps and are particularly wide spread in the food and beverage industry.

HOW ROTARY LOBE PUMPS WORK

The operating principle of the rotary lobe pump involves the accurate movement of interlocking, lobe shaped rotors to move a fixed volume through a fully sealed pump chamber. This movement is dependent on the perfectly regulated synchronisation of a corresponding set of high precision timing gears. These eliminate contact between the lobes, enabling them to handle viscous and non-lubricating fluids, as well as reducing component wear. The smooth, curved lobes minimise the presence of dead areas in the pump chamber where bacteria and other material could build up making the pump easy to clean and maintain.

The bi-directional rotation of the lobes creates and then collapse cavities, initially drawing the fluid into the pump chamber and then forcing it out of the pumping chamber. The positive displacement operation produces a low pulsation fluid flow, which means that the pump can be used with flowmeters in order to maintain the structure of the fluid. The result is a positive-displacement volumetric pump with exceptional performance. In general, flow speeds of up to 1000mӠ/h, temperatures up to 150°C, and viscosities up to100,000cst and pressures up to 30bar can be accommodated.

ROTARY working principle

Each cycle of the rotating lobes pulls in a fixed volume of fluid, this being determined by the rotational speed of the lobes. However, the fixed volume can be affected by slip, this being the amount of fluid that is recycled from the discharge side of the chamber to the suction side between the space between the lobes and the pump casing.

Slip is a key issue to consider when selecting the pump. How much slip is recycled is attributable to the viscosity of the fluid being pumped and the pump‘s differential pressure. The higher the viscosity of the fluid the less amount of slip occurs. Where the fluid has a lower viscosity, slip will increase due to the easier flow to the suction side. This leads to an increase in the discharge pressure because the pump is working harder to move the fluid from the suction side to the discharge side. Calculating the impact of back slip pump performance can be addressed by plotting a pump curve, a process that is readily undertaken by AxFlow.

Because the lobes do not come into contact, the rotary lobe can handle a range of fluid viscosities and solids-laden media. This means that clearances between the lobes are not as close, thereby enabling the pump to handle both high viscosity and lower viscosity fluids. These are attributes that make this pump type perfectly suited to handling, creams, slurries and solids-laden media. The size of the particles contained within the fluid being pumped can be much larger in lobe pumps than in other types of positive displacement pumps. Further, the gentle action of the pump will prevent fluids from shearing or damaging delicate solids.

FEATURES AND BENEFITS OF ROTARY LOBE PUMPS

- Large flow range

- Compact design and build make for easy installation and a small footprint area.

- Variety of material options for casings and rotors cater for challenging and hygienic environments.

- Low maintenance costs and ease of disassembly reduce downtime.

- Suitable for SIP, CIP and COP cleaning regimes.

- High suction capabilities enable self- priming.

- Dry run capability for limited time. However, it will affect the seal unless it is flushed.

- High levels of accuracy and efficiency.

- Reversible flow.

- Continuous low pulsation flow.

- Low shear rate reduces harm to sensitive media.

- Able to pump both high and low viscosity media.

- Multiple connection configurations for a variety of installations.

Typical Applications for Lobe Pumps

Commonly associated with food processing, rotary lobe pumps are equally as effective in personal care products, pharmaceuticals, biopharmaceuticals, chemical processing, paints, paper and pulp, minerals processing and water treatment. Each industry sector does present its own challenges, which is why AxFlow offers pumps in many different materials, builds and finishes compliant with international regulatory standards where relevant to the application.

Of the many industry sectors that are driving the growth in demands for pumps, food, beverage and personal care products processing have been identified as being key players. As standards of living improve and populations grow, the pressure is on manufacturers to produce larger volumes of processed foodstuffs and healthcare products more economically and to higher standards of quality.

Rotary lobe pumps satisfy these requirements due to the gentle action of the lobes, which reduce shear and allow delicate solids to pass through the pump without damage. In these sectors the nature of the pumped media does vary considerably. Whereas foods, such as dairy and confectionery products do not contain any abrasives, other products including chocolate, toothpastes and sauces can contain abrasives and acids which may attack the surface of the lobes and pump casing.

A much-appreciated advantage in food and personnel care products is the constant flow which satisfies the requirements of filling lines. It is essential that a constant, low pulsation flow is guaranteed at all times, for if does not there is the possibility that production lines downstream of the pumps system will fail. The end result is system down time and product wastage, all of which have an impact on costs and profitability.

In the paints, coatings, ceramics, paper and pulp industries shear-free pumping and resistance to attack from chemicals or aggressive slurries are basic requirements. These are also considerations in water treatment where grit and fats in the water, along with chemicals used in treatment processes, are present. In order to accommodate these challenges, pumps are available in a range of robust materials and with specialist surface treatments and elastomers.

AxFlow’s portfolio of rotary lobe pumps is extensive, bringing together the many technologies that give this pump type its versatility, high levels of performance and proven efficiencies. The scope of applications and breadth of industries where, and in which, it can be it used is considerable.

WHY BUY ROTARY LOBE PUMPS FROM AXFLOW

We specialise in hygienic lobe pumps and large lobe pumps for industrial applications.

AxFlow holds over 1,600 lobe & ECP pumps in stock which us to offer a reliable delivery on bare-shaft pumps of 2-3 days and new pump-sets of under 3 weeks.

To support our pumps in the field, AxFlow holds over 128,152 spare hygienic pump components and kits in stock available on a standard 2-3 or express 24-hour delivery.

We offer three types of rotary lobe pump design.

- Rubber lined lobe pumps for industrial applications.

- Hygienic rotary lobe pumps for low to medium viscosity applications.

- External circumferential piston pumps for more demanding and exacting hygienic duties.

The Waukesha external circumferential piston pump (ECP) design evolved from the traditional lobe pump design. The long sealing path of the winged rotors reduces slippage and offers gentle handling of particulates. They perform better with liquids which require gentle handling, low viscosity, and high viscosity or contain abrasives.

For more details on the ECP pump design click here.

Rotary Lobe Pump Maintenance

- Rotary lobe pumps usually have both bearings and geared motors both the bearings and gears require lubricating on a regular basis.

- Many rotary lobe pumps use mechanical seals these need regular inspection. Particularly if the mechanical seal has bearing oil on the outboard side that could leak into the fluid being pumped.

If you encounter a reduction in performance over time be this flow or pressure, then the internal components may have worn. The solution to this issue is to replace the lobes/wings with oversized replacements and reduce the internal wall thickness to maintain the original tolerances.

Specific maintenance requirements may vary depending on the brand and model of your rotary lobe pump. Always refer to the specific manufacturer's documentation and gudelines for detailed instructions and recommended maintenance intervals

How to Select Rotary Lobe Pumps

-

Fluid Compatibility: Ensure that the Lobe pump is compatible with the fluid you intend to transfer. Factors to consider may range from chemical composition, viscosity, temperature, and abrasiveness.

-

Flow Rate and Pressure Requirements: Determine the required flow rate and the desired discharge pressure, ensuring that the Lobe pump's capacity correlates with your application.

-

Fluid Viscosity: Confirm that the pump can handle the viscosity of the fluid being pumped. Some applications involve highly viscous or shear-sensitive fluids, which may require specific rotor configurations.

-

Solid Handling Capability: If your application involves pumping solids, such as food particles or slurry, choose a pump with the appropriate rotor design and clearance to accommodate solids without clogging.

-

Cleanability and Sanitary Requirements: In industries like food, pharmaceuticals, or cosmetics, consider the pump's cleanability and ability to meet sanitary standards to prevent contamination.

-

Material Compatibility: Ensure that the materials used in the pump's construction are compatible with your fluid and won't corrode or degrade over time.

-

Temperature Range: Verify that the pump can handle the temperature range of your application, especially if it involves hot or cold fluids.

-

Maintenance and Serviceability: Assess the ease of maintenance and availability of replacement parts. Some pumps are designed for quick and straightforward maintenance.

-

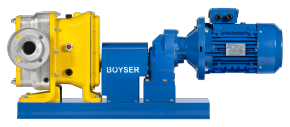

Manufacturer Reputation and Support: Choose a reputable Lobe pump manufacturer, AxFlow supply Rotary Lobe pumps from APV and Boyser

Always be cautious when it comes to using a smaller model running at a faster running speed as this could be the most expensive option when you include maintenance costs.