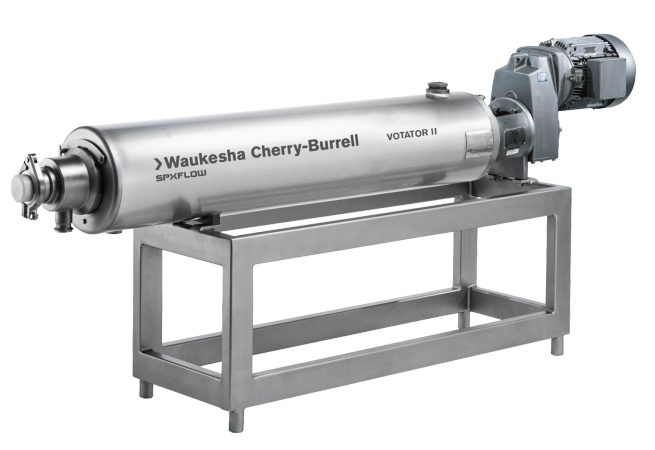

Waukesha Cherry-Burrell Votator II

SubCategory: ScrapedSurfaceHeatExchangers

Manufacturer: WaukeshaCherryBurrell

Industry:

Key specifications

- Pressure Up To 56 bar

FEATURES AND BENEFITS

- Strong vessel construction.

- No gaskets.

- 4 different profiles.

- Higher temperatures.

- Higher viscosities.

- Display a low pressure drop.

- Fully cleanable

Description

Waukesha Scraped Surface Heat exchangers continue to replace many slow, inefficient batching operations with more uniform, controllable, and repeatable processing. Their superior heat transfer performance and ability to handle a wide range of viscosities along with high fouling characteristics makes them the clear choice over tubular or massive plate heat exchangers in viscous applications.

Energy and cost efficient.

Consistent.

Good with viscous products and those prone to crystallise.

Easy to maintain.Suitable for aseptic applications.

The constant agitation results in more consistent heating or cooling and eliminates stagnant areas.

Gear motor drive - no couplings, belts or sheaves.

Can be mounted vertically or horizontally.

We put the proof in the process.

Waukesha Cherry-Burrell's Proving Center has the capability to test everything from the most viscous to the thinnest fluids...from cheese sauces and industrial tars to soups and paper coatings. If we can pump it, we can test it. For heating or cooling the most variable products from margarine to meat, or from polymers to pudding, we have the right solution.