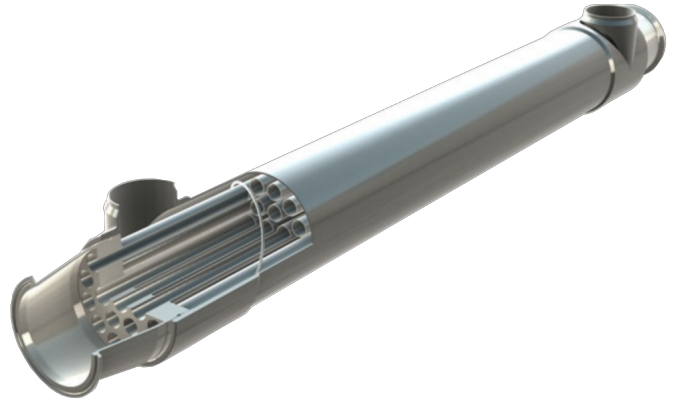

APV P2P Tubular Heat Exchanger

SubCategory: TubeInTubeHeatExchangers

Manufacturer: APV

Industry:

Key specifications

- Flows up to 30 m³/h

- Pressure Up To 30 bar

Description

In response to an ongoing drive in the dairy and beverage industries to improve energy efficiency and food safety; APV has developed a new, patented direct product regenerative Product-to-Product (P2P) type of THE. This latest heat transfer solution has the highest hygienic standards and offers increased heat transfer efficiency over a traditional THE; reducing energy consumption, size and capital investment. The new unit brings a step-change in hygienic aseptic design and sterility safety for this type of technology.

Less energy consumption

The design of the new module does not require a secondary heating/cooling water circuit loop, reducing associated heat transfer and pump energy losses. It also produces a better flow pattern on the secondary side of the THE compared to traditional solutions to improve heat transfer efficiency and lower energy consumption required for the process.

Proven ‘cleanability’

The tubes on the SPX P2P are manufactured so the secondary sides are completely smooth. This unique new design ensures complete ‘cleanability’ for hygienic use on both, the primary and the secondary side of the THE. With absolutely no crevices on the secondary side of the unit, the risk of product remaining in the unit after cleaning is eliminated and food safety is maximized. This further assures that, with no product buildup, efficiency remains optimized and production stable. This advanced cleanability has been fully tested and the unit is further designed according to EHEDG guidelines (approval pending).

Space saving d esign

The exceptional heat transfer efficiency of the SPX P2P THE means a smaller footprint is required to achieve the required thermal duty compared to standard THE units. A complete process plant can have a significantly reduced footprint with less THE modules compared with other designs.

Less process equipment

The unit requires a simple secondary circuit. As such, the amount of supporting equipment, including pumps, valves, pipework etc., that requires additional investment and maintenance is reduced.

Rapid maintenance

To ensure reduced maintenance overhead, the inner tube bundle on the P2P THE can be easily dismantled for visual inspection of cleaning results. Assured cleaning and prevention of product buildup further optimize required service intervals.

No crevices

Crevices offer bacteria places to hide during sterilization and cleaning cycles, meaning the sterility of UHT products cannot be guaranteed. The SPX P2P THE module uses a unique design that has no crevices between the tube sheet and the tubes; eliminating the associated hygiene risk. This enables it to be used in a P2P configuration with assured sterility of product on the secondary side. The new, patented design is manufacturing using advanced techniques to create a smooth, easily cleanable radius between the tubes and the tube sheets.