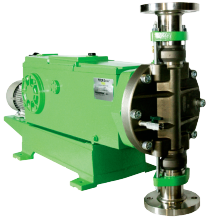

The definition of dosing varies from industry to industry as different applications require different levels of accuracy and flow. Consequently, we offer a range of dosing pumps capable of dosing to different levels of flow and accuracy.

Our range of specially selected dosing pumps includes AOD dosing pumps for general doing purposes to precise metering pumps and also includes high pressure dosing pumps in the form of piston and plunger pumps. All of our range is available across the UK.

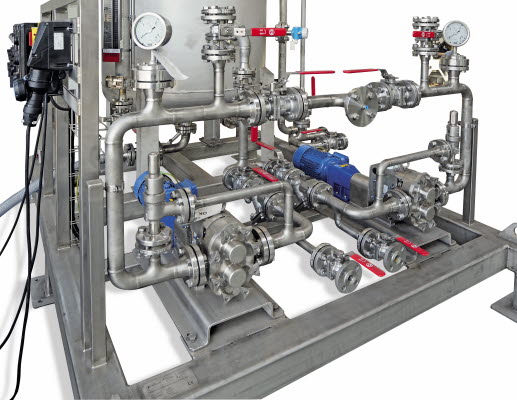

Dosing pumps are used in various industries and applications, and are primarily employed in settings that require precise and controlled dosing or metering of fluids or chemicals. One common area where dosing pumps find extensive use is in water treatment processes. They play a crucial role in adding chemicals like disinfectants, coagulants, and pH adjusters to ensure clean and safe water supply. Dosing pumps are also utilized in the agriculture sector for fertilization, where they accurately dispense nutrients and pesticides to optimize crop growth.

In industrial applications, dosing pumps may be used for adding additives, lubricants, and corrosion inhibitors to maintain the performance and longevity of machinery and equipment. Moreover, dosing pumps are utilized in the pharmaceutical and healthcare sectors for precise medication administration and laboratory processes.

Please click the icon .....