Ferric chloride (FeCl₃) is widely used as a coagulant in water and wastewater treatment, and as an etchant or catalyst in various chemical processes. In solution it is highly corrosive, oxidising, and can cause rapid attack on unsuitable metals and elastomers. Concentrated ferric chloride may also crystallise at lower temperatures or around minor leaks.

Because of this, pumps for ferric chloride must combine chemical resistance, safe containment, and reliable hydraulics over the full operating range of concentration and temperature.

AxFlow's UK wide product range includes Titanium pumps along with numerous plastic and plastic lined pumps that can resist Ferric Chloride.

Typical Ferric Chloride Pumping Duties

Ferric chloride is commonly pumped for:

- Bulk transfer from road tankers, IBCs, or drums into storage tanks

- Transfer from storage to day tanks or dosing systems

- Circulation in preparation/mixing tanks to maintain uniform strength

- Feed to dosing skids for water and wastewater treatment plants

- Handling spent or partially reacted ferric chloride streams

Most duties are low- to medium-viscosity, but density is relatively high and crystallisation risk increases at lower temperatures.

Technical Requirements for Ferric Chloride Service

Materials & Compatibility

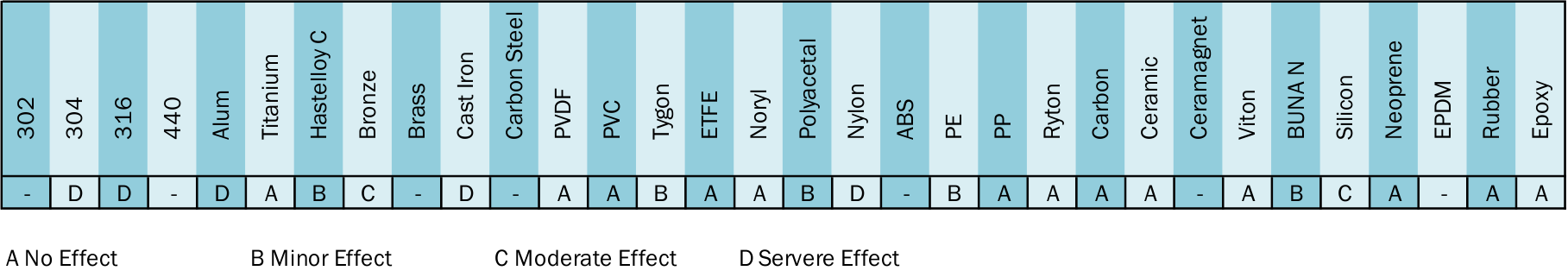

Ferric chloride is strongly corrosive to carbon steel and many stainless steels, particularly at higher temperatures and concentrations. Suitable wetted materials are critical, for example:

- Thermoplastics such as PVC, CPVC, PP, PVDF

- Rubber-lined or fluoropolymer-lined metallic pumps in some cases

- Elastomers and seals carefully selected to resist oxidation and high chloride content

Material choice must consider concentration, temperature, and any contaminants (e.g. HCl, metals, solids).

Sealing & Containment

Due to its corrosive and staining nature, leaks are both a safety and housekeeping issue. Common approaches include:

- Seal-less pumps (mag-drive centrifugal, canned motor, or AODD) to minimise shaft-seal leakage risk

- Robust mechanical seal arrangements where required, with compatible faces, elastomers, and metallic parts

- Pipework and connections designed to minimise dead zones where crystallised ferric can form and damage seals or threads

Hydraulics & Operation

Ferric chloride solutions are typically low-viscosity but relatively dense and sometimes carry fines or sludge, especially in waste streams. Pump selection should account for:

- Stable operation at the required head and flow without running far off the best-efficiency point

- Adequate NPSH margin, particularly where tanks are unvented, levels are low, or temperature is elevated

- Ability to drain and flush the pump and lines to prevent crystallisation during shutdowns