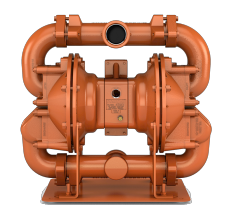

Solids Handling AODD Pumps

Solids handling pumps from Wilden, selected by AxFlow for a premium UK offering

Solids-handling AODD pumps

Solids-handling AODD pumps (air-operated double diaphragm) are widely used for slurries, sludge, abrasive liquids and suspended solids because they combine positive displacement pumping with large internal clearances and sealless operation. For many industrial and wastewater duties, they provide a reliable way to transfer difficult fluids that can clog or wear other pump types.

Why AODD pumps are good for solids

AODD pumps move liquid by alternately flexing two diaphragms, using check valves to control flow direction. Because there’s no impeller and no tight internal tolerances like a centrifugal pump, solids can pass through more easily. Key advantages include:

- Passage of large particles (model-dependent) through the pump’s valve and chamber geometry

- Tolerance of abrasive and fibrous media, common in sludge and wastewater

- Sealless design (no rotating shaft seal) which helps reduce leakage risk on dirty or aggressive fluids

- Self-priming and run-dry capability (typical for AODD designs), useful on sumps, IBCs and intermittently fed lines

Typical solids applications

Solids-capable AODD pumps are commonly specified for:

- Wastewater sludge and thickened sludge transfer

- Slurries (mining, ceramics, lime, pigments)

- Filter press feed (where pressure rises during the cycle)

- Sump and pit pumping (including raggy liquids)

- Chemical precipitates / crystallising products

- Food and beverage by-products (where suitable hygienic configurations are used)

What “solids-handling” depends on

Not all AODD pumps handle solids equally. Real performance is driven by three main factors:

1) Check valve type

- Ball check valves are common and robust, but can struggle with long fibres/rags.

- Flap or duckbill valves can be better for stringy, fibrous or shear-sensitive solids.

Choosing the right valve style is often the biggest deciding factor for clog resistance.

2) Solids size, shape and concentration

A single “max solids size” figure is not the full story. Flat, stringy or compressible solids can bridge and block even when they’re smaller than the stated limit. You’ll get best reliability by specifying the pump around:

- largest realistic particle size

- solids loading (% by weight/volume)

- whether solids are hard/abrasive vs soft/fibrous

3) Diaphragm and wetted materials

Abrasive slurries require durable elastomers and wear-resistant wetted parts. Material selection should be based on both chemical compatibility and abrasion resistance.

Performance tips for slurries and sludge

To keep a solids AODD pump stable and reduce blockages:

- Keep suction lines short and generously sized to avoid inlet starvation

- Use fewer fittings and gentle bends on suction to reduce pressure drop

- Run at an appropriate cycle rate (too fast can cause valve “chatter” and poor filling)

- Consider an air regulator and correct air plumbing to maintain consistent stroke control

- Add strainers only if they won’t rapidly blind; often it’s better to choose a more suitable valve style/pump size

Choosing the right solids-handling AODD pump

- For the best match, you’ll want to specify:

- fluid type (sludge/slurry), temperature and viscosity

- solids size, type (abrasive/fibrous), and concentration

- required flow rate and discharge pressure

- suction conditions (lift, pipework layout, tank/pit details)

- chemical compatibility requirements