What makes Ovatio Special

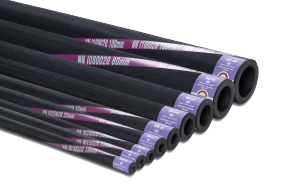

With over fifty years of expertise in peristaltic technology, hose pumps, and industrial processes, our OVATIO hoses have become pioneers in both design and manufacturing technology. This is primarily due to their high resistance to abrasion and wear even at high rotational speeds, flexibility, and consistent wall thickness with a perfectly smooth surface.

The peristaltic hoses and lubricants you use in your processes are as vital as the pumps themselves. Our OVATIO hoses, designed to fit most peristaltic pumps on the market such as Abaque and Bredel, are engineered to optimize pump operation and withstand the most demanding pumping tasks.

Advantages of OVATIO Hoses

- Nine-layer construction

- Highly flexible

- Long lifespan

- Abrasion resistance

- Pressure up to 16 bar

Applications

OVATIO hoses offer a broad chemical compatibility range, making them suitable for aggressive, abrasive, and shear-sensitive fluids. They are particularly useful for pumping acids, corrosive oils, detergents, ketones, or alcohols.

Specifications

|

Material |

Max Temperature |

Working Pressure |

Properties |

|

NR |

80°C |

16 bar |

Versatile hose with excellent resistance to abrasion, diluted acids, and alcohols. Generally suitable for mildly corrosive chemical applications or abrasive slurries. |

|

NBR |

80°C |

16 bar |

Hose with an inner layer of NBR and an outer layer of NR to ensure optimal mechanical resistance and resistance to oils, alkalis, fats, and detergents. |

|

NBR FOOD |

80°C |

16 bar |

For all food products, including oils and fats. Inner layer made from black food-grade NBR approved for hygienic applications, outer layer made from NR for optimal mechanical resistance. Complies with food standards EC 1935/2004. |

|

EPDM |

90°C |

16 bar |

High chemical resistance to corrosive chemicals, concentrated alkalis, and ketones. Inner layer made from EPDM, outer layer made from NR. |

|

Hypalon/CSM |

80°C |

16 bar |

For highly corrosive products and highly concentrated acids. Inner layer made from Hypalon/CSM, outer layer made from NR. |

Why buy from AxFlow

Drawing on more than 50 years of peristaltic hose pump technology and industrial processes, pushed our hoses into the very forefront of hose design and manufacture. As you would expect, they are manufactured to withstand even the very toughest pumping task.

AxFlow offers fluid handling equipment for the widest range of industries and applications. Only at AxFlow do you receive individual advice from industry-experienced process engineers and the selection of the world's leading process technology equipment. Do you need support in selecting the right pump for your needs? Do not hesitate to get in touch. AxFlow's experts and engineers can provide guidance for selecting, specifying, installing, and maintaining your pump

Bredel Hose Direct Replacements

Our hoses have displayed equivalent durability as Bredel hoses but at a much lower price, providing a cost-effective solution to replacement bredel hoses for various operating conditions.

AxFlow / BREDEL COMPATIBLE HOSE CROSS REFERENCE TABLE

AxFlow hose design eliminates the common problems of:

- Tear and abrasion resistance (both through their unique mix of polymer/rubber compounds and our vulcanization process)

- Rebound effect (through a unique combination of nylon cord reinforcement layers)

- Inconsistent wall thickness and uneven surfaces (through very tight manufacturing tolerances)