At AxFlow, we take pride in being industry leaders in the field of hygienic pumps for food and pharmaceutical applications. Our commitment to quality, innovation, and expertise makes us your trusted partner in addressing your specific hygienic pump requirements

WHAT MAKES A PUMP HYGIENIC OR SANITARY

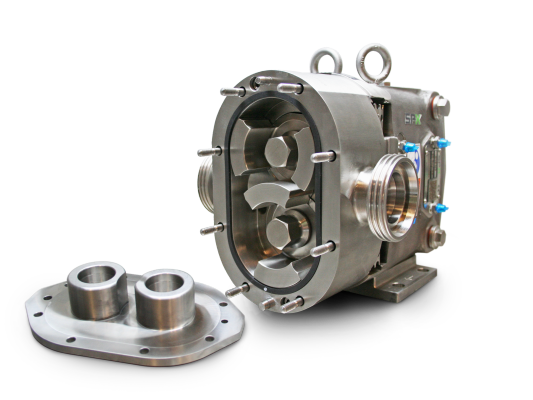

There are many different levels of "hygienic" or "sanitary" when it comes to pumps. These range from standard pumps that use FDA approved materials, pumps that are constructed to be easy to dis-assemble and cleaned through to pumps with internal designs that make it difficult for bacteria to find surfaces on which to breed. EHEDG and 3-A certification provide assurance that a pump's design is truly hygienic.

Hygienic pump designs concern themselves with three main areas:

- component profiles that have no flat surfaces or crevices.

- Polished surfaces

- Internal designs that allow them to be cleaned in place (CIP).

WHY buy hygienic pumps from axflow

Our Hygienic Pump Portfolio

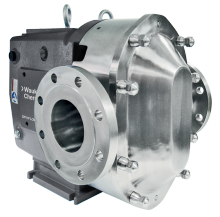

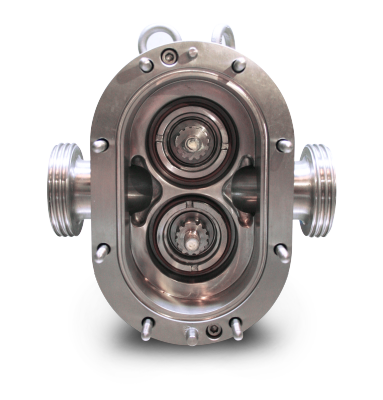

- Hygienic Rotary Lobe Pumps: Efficient and versatile, these pumps ensure reliable performance in various applications.

- Hygienic Eccentric Disc Pumps: Known for their precise and gentle product handling, ideal for sensitive substances.

- Sanitary AODD Pumps: Versatile and dependable, suitable for a wide range of food and pharmaceutical applications.

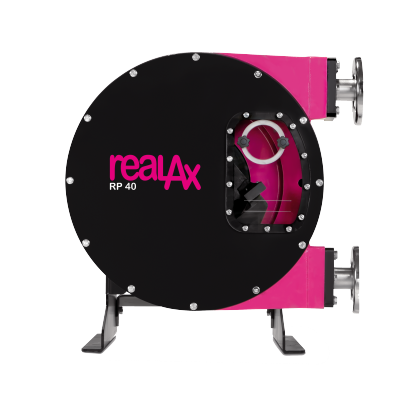

- Food Grade Hose Pumps: Designed for durability and efficiency, these pumps handle various viscosities with ease.

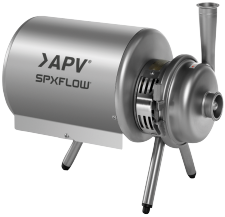

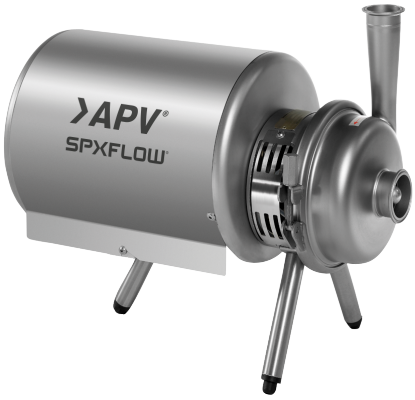

- Sanitary Centrifugal Pumps: Constructed from stainless steel, these pumps offer exceptional performance in hygienic environments.

- Food Grade Vane Pumps: Specifically engineered for pumping chocolate, these pumps ensure seamless processing.

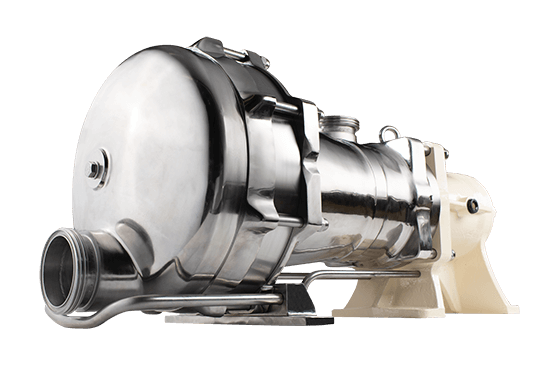

AxFlow supply the Universal TS series which is a new and innovative positive displacement twin screw pump for hygienic applications. This precision pump offers a gentle flow and the ability to pump both product and CIP therefore reducing overall process costs considerably.

AxFlow are also the industry leaders for Hygienic and Sanitary Pump repair which allows us to offer scheduled review, monitoring and maintenance services as well as re-installing your hygienic pump through on site visits.

AxFlow boasts the widest range of food grade and hygienic pumps in the UK. Our range includes many hygienic centrifugal pumps, brewery pump models for use as high viscosity pumps. AxFlow are the official UK distributor for APV within the Food & Beverage Industry.

- Wide Range of Hygienic Pumps: AxFlow offers the broadest selection of food grade and hygienic pumps, ensuring you find the right pump for your specific application.

- Expertise and Experience: With over 50 years of experience, our team possesses unparalleled knowledge in the realm of hygienic pumps, offering you expert guidance and solutions.

- Local Support: With technical pump centers strategically spread across Europe, we provide localized support, ensuring timely assistance whenever and wherever you need it.

- Official APV Distributor: AxFlow proudly serves as the official distributor for APV within the Food & Beverage Industry, offering you access to top-quality products.

- Sanitary Pump Repairs: Count on us for expert repairs of sanitary pumps, ensuring your equipment operates at peak efficiency.

- Comprehensive Stock: We maintain stocks of the most popular hygienic pump types, ensuring quick availability when you need replacements or upgrades.

Our hygienic pump portfolio covers low shear rotary lobe and eccentric disc pumps, three ranges of food grade AOD pumps, hygienic stainless steel centrifugal pumps, and vane pumps specifically designed to pump chocolate. AxFlow offers many EHEDG pumps and 3A certified pumps as well as pumps using FDA and EC1935 approved materials.

Understanding Hygienic and Sanitary Pumps

When it comes to hygienic pumps, there's a spectrum of standards, from FDA-approved materials to designs that eliminate flat surfaces and crevices, feature polished surfaces, and allow easy Clean-In-Place (CIP) cleaning. EHEDG and 3-A certifications provide assurance of a pump's genuinely hygienic design.