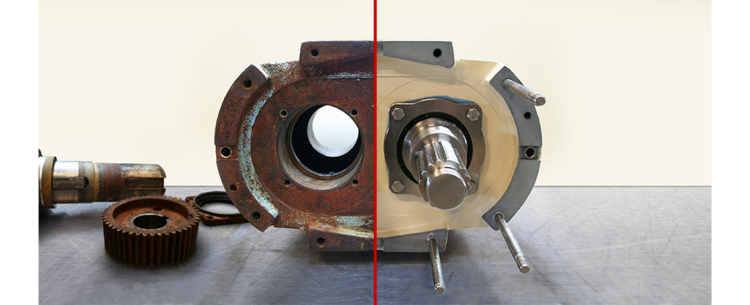

Pump servicing & repair solutions

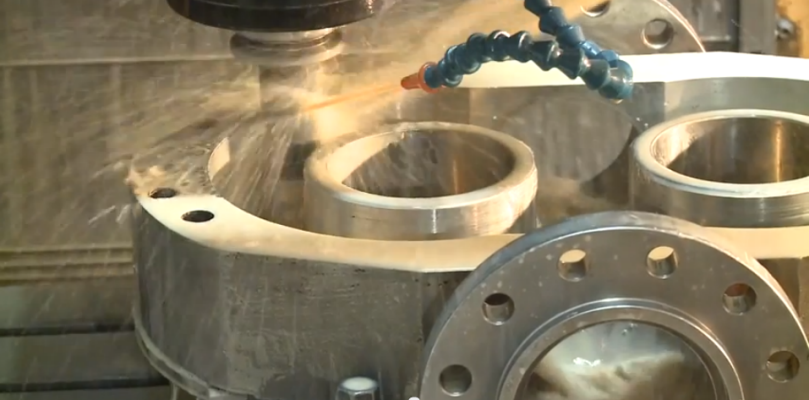

AxFlow are experience pump repairers and offer a full range of pump repair capabilities including in-house machining, Belzona coating, dynamic balancing, mechanical seal overhaul, metal spraying and fusion welded coatings, laser alignment, hygienic pump repair and positive displacement pump repair and the ability to re-engineer a wide range of pump components.

we offer reliable and responsive pump servicing to keep your operations running smoothly. Our team of experts delivers comprehensive pump repair services for a wide range of industrial applications, ensuring your equipment operates at peak performance.

AxFlow is one of the UK's biggest pump repair companies.

Centrifugal Pump Repair which includes all types of process pump including ATEX pumps, ISO 5199 , mag drive and canned.

Positive Displacement Pump Repair area that AxFlow excels in due to our position as the leading supplier of positive displacement pumps in the UK.

Heritage Brand Pump Repair with over 25 years of experience, a fully equipped machine shop and the ability to remanufacture obsolete components.

Mechanical Seal Refurbishment supported by the latest measurement and lapping equipment.

Hygienic Pump Repair carried out in a dedicated clean room.

Submersible Pump Repair AxFlow have extensive experience of submersible pump repair including numerous examples of major infra structure assets.

WHY USE AXFLOW FOR YOUR PUMP REPAIR & Maintenance

- AxFlow can carry out pump service work on site or, bring your pump to our local repair centre if required.

- AxFlow can carry out pump installation for repaired pumps of any size.

- We have over 50 years of pump refurbishment experience.

- AxFlow are experts when it comes to all types of pump repair.

Our repair services can extend the life of your equipment, improve energy efficiency, and reduce your capital expenditure. Whether it’s an emergency breakdown or a scheduled refurbishment, AxFlow is your trusted partner in pump reliability.

nationwide Pump Repair Centres