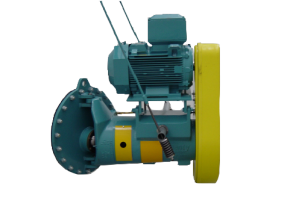

Side-entry mixers are used in various industries for mixing and blending large volumes of liquids in tanks or containers. They operate via a horizontal shaft connected to a motor, which rotates at high speeds, and the mixer blades create a flow pattern that promotes fluid mixing. Side-entry mixers are cost-effective, space-saving, and easy to maintain, making them a popular choice in the industry. They are used in industries such as oil and gas, chemicals, food and beverages, pharmaceuticals, water treatment, and mining. These mixers are designed to be mounted on the side of a tank or container and mix the liquids inside by creating turbulence through high-speed blades, making them ideal for mixing high-viscosity fluids. AxFlow offers side-entry mixers for a wide range of industries and applications, providing tailored advice from experienced process engineers and manufacturer-independent selection from the world’s leading process technology.

Side Entry Mixers

4 series from 1 manufacturers

-

- Acetate

- Acids

- Adhesives

- Alcohols

- Aluminium Oxide Slurry

- Ammonia

- Beer

- Biological Broths and Slurries

- Bitumen

- Carbon Fibers

- Caustic Solutions

- Chocolate

- CIP Fluids

- Coffee

- Cooling Water

- Corrosive Dyes

- Corrosive Liquids

- Cryogenic Liquids

- Dairy Products

- Detergents

- Diesel Fuel Oil

- Drinking Water

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Foam Protein

- Fruit and Vegetables

- Fruit Concentrates

- Gels

- Glycol

- High Temperature Oils

- High Viscosity Liquids

- Hydrochloric Acid

- Hygienic Liquids

- Irrigation Water

- Lake Water

- Latex

- Light Fluids

- Lime

- Liquid CO2

- Low NPSH

- Low Viscosity Liquids

- LPG

- Milk

- Molasses and Syrups

- Must

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Pet Food

- Phosphoric Acid

- Plastic

- Process Condensate

- Produced Water

- Redox

- Refrigerants

- Rubber

- Sauces

- Seawater

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Sewage

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Solvents

- Spirits

- Sulphuric Acids

- Surface Water

- Surfactants

- Synthetic Fibers

- Thermal Oil

- Thin Liquids

- Thixotropic Fluids

- Toluene

- Toxic Liquids

- Ultra Pure Water

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Wastewater

- Water

- Water Hardness

- Wine

- Wort

How side-entry mixers work

The operating principle of side-entry mixers involves the use of a horizontal shaft mounted on the side of a mixing tank or container. The shaft is connected to a motor and rotates at high speeds, creating turbulence and promoting efficient blending of contents in the tank.

Mixer blades or impellers are attached to the horizontal shaft. They create a flow pattern that promotes fluid mixing. These mixers can be equipped with various types of impellers, such as axial flow, radial flow, and mixed flow, depending on the specific mixing requirements. The blade shape and design can be customized for specific mixing applications such as blending, dispersion, or solid suspension.

Side-entry mixers are designed to operate at different speeds depending on the viscosity and specific gravity of the fluids being mixed. The mixer speed can be adjusted to achieve the desired mixing intensity and efficiency.

Additionally, side-entry mixers can be equipped with various accessories such as baffles and flow control devices to optimize mixing efficiency and reduce energy consumption. These accessories help reduce vortex formation and improve fluid circulation, resulting in more efficient mixing.

Advantages of side-entry mixers

Side-entry mixers offer many advantages compared to other types of mixers across different industrial sectors. Some of the key advantages of side-entry mixers include:

- Efficient mixing: Side-entry mixers are designed to provide efficient mixing of large volumes of liquid, resulting in better product quality and faster processing times.

- Cost-effective: Side-entry mixers can be installed on smaller tanks, which reduces the overall cost of the mixing system. This leads to savings in materials, maintenance, and energy.

- Versatility: Side-entry mixers can be adapted with various blade designs and accessories to suit a wide range of mixing tasks, including blending, dispersion, and suspension of solid particles.

- Space-saving in tanks: Side-entry mixers can be mounted on the tank wall, saving space compared to top-entry mixers that require larger tank openings.

- Easy maintenance: Side-entry mixers are easy to maintain and service since the motor and gearbox are located outside the tank.

- Improved safety: Side-entry mixers can be enhanced with safety features such as automatic shut-off sensors to prevent accidents and reduce the risk of injury.

Why choose AxFlow for side-entry mixers

AxFlow offers side-entry mixers for the broadest range of industrial sectors and applications. Only at AxFlow will you receive personalized advice from experienced process engineers and access to manufacturer-independent selection from global leaders in process technology. Need help selecting the right mixer for your needs? Don’t hesitate to contact us. AxFlow experts and engineers can advise, specify, install, and support your fluid handling equipment.