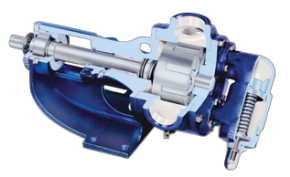

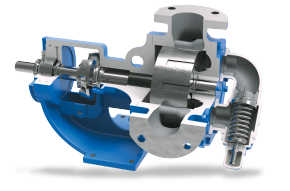

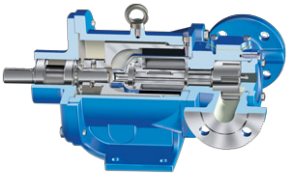

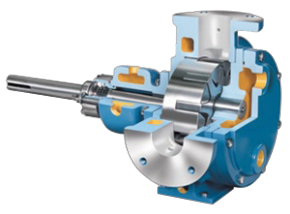

Internal gear pumps operate using two interlocking gears, one nested inside the other. They rotate in opposing directions, creating a suction force that draws fluid into the pump, and when the gear teeth mesh, it pushes the fluid out.

Internal Gear Pumps

11 series from 1 manufacturers

-

- Adhesives

- Agriculture

- Bakery and confectionery

- Beauty & Personal Care

- Building Services

- Ceramics

- Chemical

- Detergents

- Dye & Pigment

- Emulsions

- Food & Beverage

- Heating, Water & Sanitation

- Mechanical Engineering

- Nuclear Power Plants

- Offshore

- Oil & Gas

- Paper Mills

- Petrochemical

- Power Generation

- Water Treatment

-

- Analysis

- Booster

- Circulation

- Cleaning

- Control

- Conveying

- Cooling

- Descaling

- Desinfection

- Dewatering

- Diagnostic

- Discharge

- Distribution

- Dosing

- Drain

- Drainage

- Dual Dispensing

- Feed

- Filling

- Filtration

- Flow Control

- Greasing

- Grinding

- Handling

- Heating

- High-Pressure

- High-Temperature

- High-Volume

- Injection

- Irrigation

- Level Control

- Lift

- Lifting

- Loading

- Low-Pressure

- Lubrication

- Medium-Pressure

- Metering

- Off-loading

- Powder Coating

- Pressurisation

- Process

- Processing

- Recirculation

- Recovery

- Refueling

- Replacement

- Rinsing

- Sampling

- Settling

- Spraying

- Tempering

- Transfer

- Treatment

- Unloading

- Volumetric Dispensing

- Washing

- Water-Jet Cleaning

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Alcohols

- Aluminium Oxide Slurry

- Ammonia

- Bitumen

- Carbon Fibers

- Caustic Solutions

- China Clay Slurry

- Chocolate

- CIP Fluids

- Clay

- Cooling Water

- Corrosive Dyes

- Corrosive Liquids

- Cryogenic Liquids

- Crystalline Slurry

- Detergents

- Diesel Fuel Oil

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Ferric Chloride

- Fertilizers

- Foam Protein

- Gels

- Glycol

- High Temperature Oils

- High Viscosity Liquids

- Hydrochloric Acid

- Irrigation Water

- Lake Water

- Latex

- Light Fluids

- Liquid CO2

- Low NPSH

- Low Viscosity Liquids

- LPG

- Molasses and Syrups

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Phosphoric Acid

- Plastic

- Process Condensate

- Produced Water

- Radio Active Fluids

- Redox

- Refrigerants

- Rubber

- Seawater

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Sewage

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Solvents

- Spirits

- Sulphuric Acids

- Surface Water

- Surfactants

- Synthetic Fibers

- Thermal Oil

- Thin Liquids

- Thixotropic Fluids

- Toluene

- Toxic Liquids

- Ultra Pure Water

- Vegetable Oils

- Viscose

- Viscous Liquids

- Wastewater

- Water

- Water Hardness

-

- Abrasion Resistant

- Adjustable-Flow

- Chemically Resistant

- Close-Coupled

- Compact

- Corrosion-Proof

- Direct-Drive

- Electric

- Explosion-Proof

- Flange

- Heavy-Duty

- High Temperature

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- In-Line

- Intrinsically Safe

- Low Shear

- Mechanical

- Mechanical Seal

- Oil-Free

- Pulse-less

- Rotary

- Self-priming

- Solids Handling

- Variable Speed

Do you need help finding the right pump that meets your needs?

We have experienced experts who are reay to help you!

Get in touch hereOperating Principle of Internal Gear Pumps

Internal gear pumps operate through the interaction of an outer gear with external teeth and an inner gear with internal teeth within a housing. The smaller inner gear is positioned inside the larger outer gear, and as they rotate, their teeth mesh, trapping and moving fluid from the suction port to the discharge port. This process starts with fluid being drawn into the pump through the suction port as the gears rotate, creating expanding cavities and a low-pressure zone that sucks in the fluid. As they continue to rotate, the cavity size decreases due to the meshing of the gear teeth, which compresses and displaces the fluid towards the discharge port. The gears maintain close tolerances with the pump housing to minimize leakage and ensure a consistent volume of fluid is displaced with each revolution, a mechanism known as positive displacement. Additionally, the flow rate of the pump is proportional to the speed of gear rotation, allowing for precise control over fluid delivery by adjusting the gear speed.

Advantages of Internal Gear Pumps

- Viscosity Handling: Ideal for transferring high-viscosity fluids.

- Versatility: Handles various viscosities and small solid particles.

- Performance: Suitable for high-pressure and high-flow applications.

- Adaptability: Functions well in challenging conditions like high temperatures and low Net Positive Suction Head (NPSH).

- Self-Priming: Capable of frequent starts and stops.

- Applications: Widely used in industries like asphalt production, chemical manufacturing, oil and gas, and food and beverage.

Applications of Internal Gear Pumps

- Asphalt & Bitumen Production: Effective in handling sticky substances in large-scale production.

- Chemical Industry: Used for precise metering and transferring of ingredients.

- Oil & Gas Sector: Reliable in high-pressure applications.

- Food & Beverage: Ensures accurate transfer and metering of ingredients.

|

Application |

External gear pump |

Internal gear pump |

|

Acids and caustics |

x |

|

|

Agricultural |

x |

|

|

Alcohol and solvents |

x |

x |

|

Asphalt, bitumen and tar |

|

x |

|

Chemical additives |

x |

x |

|

Chemical mixing and blending |

x |

|

|

Cooking oil filtration / reclamation |

x |

x |

|

Cooling liquids for electric car fast chargers |

x |

|

|

Food products (e.g. corn syrup, peanut butter, vegetable fats/oils, etc.) |

|

x |

|

Fuels and fuel oils |

x |

x |

|

Glycol |

|

x |

|

Industrial and mobile hydraulics |

x |

|

|

Isocyanates & polyols |

x |

x |

|

Liquid transfer in fuel cells |

x |

|

|

Lube oils |

x |

x |

|

Paint, ink and pigments |

|

x |

|

Polymers metering |

x |

x |

|

Resins and polymers |

|

x |

|

Soaps and surfactants |

|

x |

Why buy internal gear pumps from AxFlow?

AxFlow provides a diverse range of internal gear pumps tailored to various industries. Our experts offer comprehensive support, aiding in pump selection, specification, installation, and maintenance. Reach out to AxFlow for personalized guidance in choosing the ideal internal gear pump for your specific requirements.