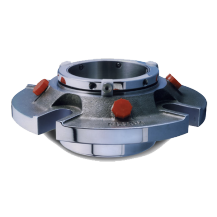

Mixer seals are critical components in industrial mixing and agitation systems, ensuring the containment of process fluids and preventing leaks along rotating shafts. Their robust design accommodates the complex dynamics of mixers and agitators, offering reliable performance across various industries. By maintaining the integrity of mixing processes, these seals contribute to operational efficiency and safety.

Mixer Seals

1 series from 1 manufacturers

The Operating Principle of Mixer Seals

Mixer seals function by creating a secure barrier between the rotating shaft and the stationary mixer housing, preventing process fluids from escaping and contaminants from entering. This is achieved through precisely engineered seal faces that maintain contact under varying pressures and shaft movements, ensuring a consistent seal during operation.

To accommodate the unique challenges posed by mixer applications, such as shaft misalignment and radial movement, mixer seals often incorporate flexible elements and advanced materials. These features allow the seal to adapt to dynamic conditions, maintaining effective sealing performance even in demanding environments.

The Advantages of Mixer Seals

Implementing mixer seals in industrial applications offers numerous benefits:

- Leak Prevention: Effectively contain process fluids, reducing the risk of leaks and ensuring environmental safety.

- Operational Efficiency: Maintain consistent performance, minimizing downtime and enhancing productivity.

- Adaptability: Constructed to accommodate shaft misalignment and radial movement, ensuring reliable sealing in dynamic conditions.

- Contamination Reduction: Prevent external contaminants from entering the process, preserving product purity.

- Extended Equipment Life: Reduce wear on mixer components by maintaining proper lubrication and alignment.

- Versatility: Suitable for a wide range of industries, including chemical, pharmaceutical, and food processing.

- Compliance: Meet stringent industry standards for safety and performance.

- Cost-Effective Maintenance: Modular designs facilitate easier inspection and replacement, reducing maintenance costs.

Why Buy Mixer Seals from AxFlow

At AxFlow, we recognize the pivotal role that effective sealing solutions play in your mixing and agitation processes. Our comprehensive range of mixer seals is engineered to address the diverse requirements of various industries, delivering exceptional performance and reliability. By partnering with AxFlow, you gain access to our extensive technical expertise, unwavering commitment to quality, and tailored solutions designed to optimize your operations. Experience sealing solutions that enhance efficiency and longevity with AxFlow.