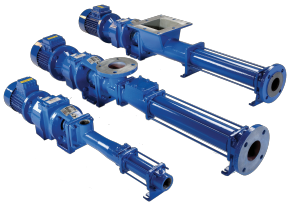

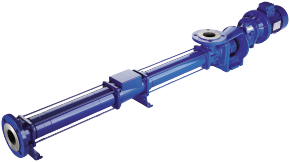

Progressive cavity pumps are positive displacement pumps featuring a spiral, helical rotor. These pumps deliver a continuous, low-pulsation flow and can handle high-viscosity and temperature-sensitive materials with minimal shear and almost no pulsation. They are cost-effective, require minimal maintenance, and can be used both for precise dosing and for transferring liquids over long distances. Thanks to their low shear and pulsation characteristics, they are ideal for handling liquids containing solid particles or those requiring gentle treatment. AxFlow offers pumps and support for a wide range of industries and applications.

Progressive Cavity Pumps

8 series from 1 manufacturers

-

- Acetate

- Adhesives

- Agriculture

- Bakery and confectionery

- Beauty & Personal Care

- Brewing and beverages

- Building Services

- Ceramics

- Chemical

- Clay

- Confectionery

- Convenience food

- Dairy

- Detergents

- Dye & Pigment

- Fertilizers

- Food & Beverage

- Heating, Water & Sanitation

- Meat Processing

- Mineral Products

- Mining

- Oil & Gas

- Oil Fats & Mayonnaise

- Paint & Surface Coating

- Paints & Resins

- Paper Mills

- Petrochemical

- Pharmaceutical

- Power Generation

- Research & Development

- Sugar Processing

- Surface / Pit

- Surface Finishing

- Transportation

- Wastewater

- Water Treatment

-

- Booster

- Circulation

- Cleaning

- Control

- Conveying

- Cooling

- Descaling

- Desinfection

- Dewatering

- Discharge

- Distribution

- Dosing

- Drain

- Drainage

- Dredging

- Feed

- Filling

- Filtration

- Flow Control

- Handling

- High-Pressure

- High-Volume

- Injection

- Irrigation

- Level Control

- Lift

- Lifting

- Loading

- Low-Pressure

- Lubrication

- Medium-Pressure

- Metering

- Mixing

- Off-loading

- Pressurisation

- Process

- Processing

- Recirculation

- Recovery

- Refueling

- Replacement

- Spraying

- Transfer

- Treatment

- Unloading

- Volumetric Dispensing

- Washing

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Alcohols

- Aluminium Oxide Slurry

- Ammonia

- Beer

- Biological Broths and Slurries

- Bitumen

- Carbon Fibers

- Caustic Solutions

- Cereals

- China Clay Slurry

- Chocolate

- CIP Fluids

- Clay

- Coffee

- Concrete

- Cooling Water

- Corrosive Dyes

- Corrosive Liquids

- Cryogenic Liquids

- Crystalline Slurry

- Dairy Products

- Detergents

- Diesel Fuel Oil

- Drinking Water

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Ferric Chloride

- Fertilizers

- Foam Protein

- Fruit and Vegetables

- Fruit Concentrates

- Gels

- Glycol

- High Viscosity Liquids

- Hydrochloric Acid

- Hygienic Liquids

- Irrigation Water

- Lake Water

- Latex

- Light Fluids

- Lime

- Low NPSH

- Low Viscosity Liquids

- LPG

- Meat

- Milk

- Molasses and Syrups

- Must

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Pet Food

- Phosphoric Acid

- Plastic

- Process Condensate

- Produced Water

- Radio Active Fluids

- Redox

- Refrigerants

- Rubber

- Sauces

- Seawater

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Sewage

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Spirits

- Sulphuric Acids

- Surface Water

- Surfactants

- Synthetic Fibers

- Thermal Oil

- Thin Liquids

- Thixotropic Fluids

- Toxic Liquids

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Wastewater

- Water

- Water Hardness

- Wine

- Wort

-

- Abrasion Resistant

- Adjustable-Flow

- Automatic

- Booster Sets

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Corrosion-Proof

- Direct-Drive

- Electric

- Explosion-Proof

- Fish Friendly

- Flange

- Heavy-Duty

- High System Pressure

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- In-Line

- Intrinsically Safe

- Low Shear

- Low-Noise

- Mechanical

- Mechanical Seal

- Mixed Flow

- Mobile

- Multi-Stage

- Oil-Free

- Pulse-less

- Rotary

- Rugged

- Sanitary

- Self-priming

- Semi Submersible

- Single-Stage

- Solids Handling

- Variable Speed

- Vertical

- Vertical-Mount

Do you need help finding the right pump that meets your needs?

We have experienced experts who are reay to help you!

Get in touch hereHow do progressive cavity pumps work?

Progressive cavity pumps, also known as PC pumps, eccentric screw pumps, or helical rotor pumps, are a type of positive displacement pump. A helical screw-like rotor, resembling a wine opener, is housed inside a stator and rotates to form cavities through which the fluid flows. These cavities have a defined volume, determining the pump’s volumetric flow, which is directly related to the rotor speed. This movement causes slight deformation and virtually no pulsation. Pumping speed generally depends on pump size and the fluid being pumped. Larger pumps typically operate at lower rotational speeds, while smaller ones run faster. Pump speed can be adjusted using a gearbox or a rubber V-belt between the pump and the motor.

Advantages of progressive cavity pumps

- Efficiency and maintenance: Progressive cavity pumps are known for their durability and minimal maintenance needs. Their design enables on-site maintenance, making them a cost-effective solution for fluids with high viscosity or sensitivity to temperature.

- Flow characteristics: These pumps ensure a smooth, low-pulsation flow, making them ideal for dosing and transferring fluids containing delicate solid particles. The gentle pumping action helps prevent material damage.

- Pressure handling: Thanks to their ability to generate high pressures, PC pumps are excellent for transporting fluids over long distances, reducing the need for additional pump stages.

- Handling complex fluids: Their low internal speed and high-pressure capability make progressive cavity pumps suitable for transferring viscous, abrasive, or temperature-sensitive fluids while minimizing system wear.

- Applications: Progressive cavity pumps are commonly used where gentle material handling is crucial – in the food, beverage, cosmetics, and chemical industries, as well as in wastewater treatment and dosing systems.

Why buy progressive cavity pumps from AxFlow?

AxFlow offers progressive cavity pumps and accessories for the broadest range of industries and applications. Need help choosing the right pump for your needs? Don’t hesitate to get in touch. AxFlow experts and engineers can guide you in selecting, specifying, installing, and supporting your progressive cavity pump.