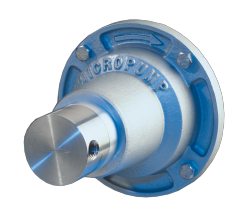

The magnetically coupled gear pumps from the manufacturer Micropump work with high precision and reproducibly reliable dosing properties. Micropump's externally toothed gear pumps are hermetically sealed so that there is no leakage loss. With their compact dimensions, they are used in many industrial machines and systems.

HOW IS HIGH DOSING ACCURACY ACHIEVED?

In externally toothed gear pumps, high dosing accuracy is achieved through the use of special technologies in the design of the pump. The patented Micropump suction shoe in the GA, GB and GC series sits spring-loaded in the pump housing and automatically compensates for its position in the event of fluctuating pressure or thematic expansion. This results in a high volumetric accuracy in the application and slippage is almost completely prevented.

ADVANTAGES OF MICROPUMP GEAR PUMPS

Precise dosing for the highest demands on reproducibility

Magnetically coupled, without mechanical seals

Hermetically sealed and without leakage loss to the environment

Compact size, ideal for OEM users

Easy maintenance through service kits

Due to their small dimensions, the Micropump gear pumps are ideal for OEM users and many industrial applications. The gear pumps are suitable for conveying and dosing chemicals, coolants, lubricants, paints and treated water.

WHERE ARE EXTERNALLY TOOTHED GEAR PUMPS USED?

Externally toothed gear pumps are used for chemical dosing in water treatment.

External gear pumps are used to convey coolants and lubricants in industrial production.

Externally toothed gear pumps are also used for dosing paints and varnishes.

What makes Micropump special

Since 1960, from our humble beginnings in a garage to our current headquarters in Vancouver, Washington, with sales offices in Europe and Asia – Micropump has been a partner for leading global companies.

Micropump moved to our first manufacturing facility in Concord, California from our first operations in our founder’s garage. Today, we deliver our products to customers worldwide under that same roof. Our 59,000 sq. ft. houses all our manufacturing, assembly, engineering, design, QA/QC, testing, shipping, and many other teams that work together to support our global customers.

Why buy from AxFlow

AxFlow offers fluid handling equipment for the widest range of industries and applications. Only at AxFlow do you receive individual advice from industry-experienced process engineers and the selection of the world's leading process technology equipment. Do you need support in selecting the right pump for your needs? Do not hesitate to get in touch. AxFlow's experts and engineers can provide guidance for selecting, specifying, installing, and maintaining your pump