What makes NOV MONO Special

NOV stands as one of the world's largest manufacturers of process technology, offering a comprehensive range of API-compliant products for the oil and gas industry, chemical and petrochemical sectors, and highly specialized equipment for water and wastewater treatment.

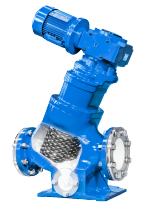

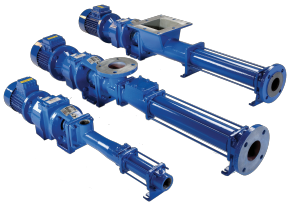

NOV MONO Progressive Cavity PUMPS

Manufactured by NOV, Mono progressive cavity pumps find application in various fields, including water and wastewater treatment, paper and pulp processing, food processing, and the chemical industry. These pumps excel in handling liquids with high solids content, abrasive materials, and shear-sensitive mixtures, showcasing exceptional durability and reliability.

Most Mono progressive cavity pump series feature the patented FlexiShaft, a component that transfers force to the rotor within the pump. The FlexiShaft replaces conventional, wear-prone universal joints and pins, significantly reducing the number of spare parts and wear-related costs.

Which Industries Does NOV Mono Serve?

For more than 70 years, NOV Mono has been designing industry-leading pump series that find application in nearly all industrial sectors. The manufacturer's products adhere to high-quality standards and are utilized in various fields, including municipal wastewater disposal, paper & pulp, ceramics, and the chemical industry.

Rely on NOV's expertise and cutting-edge technology for your process requirements, ensuring reliable and efficient solutions for your industry needs.

Why buy from AxFlow

AxFlow offers fluid handling equipment for the widest range of industries and applications. Only at AxFlow do you receive individual advice from industry-experienced process engineers and the selection of the world's leading process technology equipment. Do you need support in selecting the right pump for your needs? Do not hesitate to get in touch. AxFlow's experts and engineers can provide guidance for selecting, specifying, installing, and maintaining your pump

In our European Distribution Center (EDC) in the Netherlands, we constantly stock up to 300 NOV Mono pumps, along with rotors, stators, seals, and other original spare parts. In most cases, the desired products are delivered within 48 hours of placing the order, enabling us to prevent process disruptions over an extended period.