What do mouvex manufacture?

ECCENTRIC DISC PUMPS

Eccentric movement technology is at the core of Mouvex®. Mouvex founder Andre Petit identified the challenges that gear and lobe pump users were facing in optimizing their process and invented the eccentric disc pump as a result. Petit specifically placed a disc inside the pump cylinder so the eccentric disc would be more user-friendly. This disc is driven by an eccentric bearing that is installed on the pump shaft, thus creating four distinct pumping chambers that increase and decrease in volume as the disc is rotated by the eccentric bearing. The four chambers produce both suction and discharge pressures as the chambers move in pairs that are 180 degrees apart. This ensures that the fluid passes through the pump at a constant and regular flow rate.

Mouvex eccentric disc pumps are ideally suited for a variety of sanitary applications that require a consistent, non-pulsing flow and gentle fluid handling with low shear rates. Mouvex pumps also excel in the hygienic applications that are common in food-and-beverage, pharmaceutical and cosmetics manufacturing because they have been designed to conform with the most prevalent regulatory sanitary standards while providing gentle product handling, superior containment, and easy maintenance.

HOW MOUVEX ECCENTRIC DISC PUMPS WORK

Eccentric disc pumps consist of a cylinder and pumping element mounted on an eccentric shaft. As the eccentric shaft is rotated, the pumping element forms chambers within the cylinder, which increase in size at the intake port, drawing fluid into the pumping chamber. The fluid is transported to the discharge port where the pumping chamber size is decreased. This action squeezes the fluid out into the discharge piping.

HOW MOUVEX SLIDING VANE PUMPS WORK

Mouvex® sliding vane pumps have a number of vanes that are free to slide in to or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force, rods and/or pressurized fluid causes the vanes to move outward in their slots and bear against the inner bore of the pump casing forming pumping chambers. As the rotor revolves, fluid flows into the area between the vanes (pumping chambers) when they pass the suction port. The fluid is transported around the pump casing until the discharge port is reached. At this point, the fluid is squeezed out into the discharge piping.

WHAT MAKES MOUVEX PUMPS SPECIAL?

Mouvex pumps are best known for their reliability, durability and cost effectiveness, and have earned a reputation as the ideal pumping technology for some of the harshest applications in the world.

With more than a century of experience, Mouvex is a leader in product innovation, providing cutting-edge solutions utilizing a state-of-the-art manufacturing facility in Auxerre, France. By localizing customer support for all PSG brands, no matter where in the world you need us, the PSG Service Center in Auxerre is an example of how we deliver on the promise to make our channel partners more competitive and more successful.

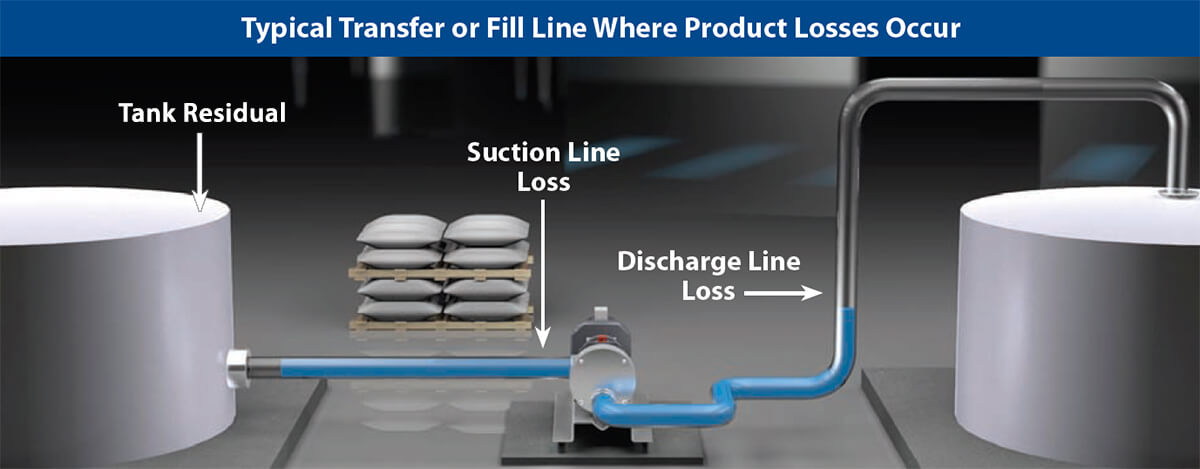

WHAT IS PRODUCT RECOVERY

In food-and-beverage, pharmaceutical and cosmetic-manufacturing applications, product recovery refers to the nearly total utilization (or yield) of products or ingredients. When performed properly, product recovery substantially eliminates the waste of useable products and ingredients that would otherwise remain in suction or discharge process lines during changeovers or at the end of production runs, thereby increasing profits. Too often, these fluids that remain in the piping, which can be some of the most expensive in the world, are just washed out and flushed down the drain. Or they're recovered only with the assistance of costly add-on components, such as pigging systems.

Pump technologies such as lobe, external circumferential piston (ECP), centrifugal, peristaltic hose and progressive cavity are often chosen to facilitate the transfer of raw and finished fluids during production. However, these pumps are not capable of adequately clearing or stripping the transfer lines of remaining materials. Basically, then, product recovery is the process of clearing or stripping lines of valuable product that can still be used, but these legacy pump technologies are often unable to satisfactorily perform those duties. There is a better option available, one that, if the right pumping technology is used, can help manufacturers achieve increased product-recovery rates of 60% to 80%.

ADVANTAGE OF MOUVEX IN PRODUCT RECOVERY

The key to optimizing product recovery and, by extension, profit recovery is identifying and employing the most efficient and reliable pumping technology, one that can be trusted to reliably strip suction or discharge lines of valuable raw materials and salable end-products. For more than a century, eccentric disc pump technology from Mouvex® has stood ready to optimize product recovery rates thanks to an operating principle that provides non-pulsing, low-slip operation with high volumetric consistency. Mouvex pumps are also able to pump air, which creates a vacuum effect on the pump's suction side and a compressor effect on the discharge side. This produces a plug effect that pushes a complete and still useable product "plug" out of the piping.