What makes Wilden Special

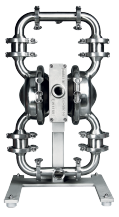

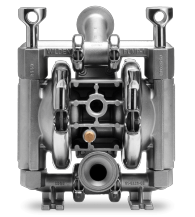

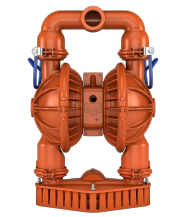

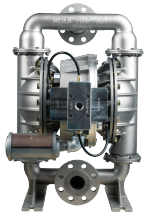

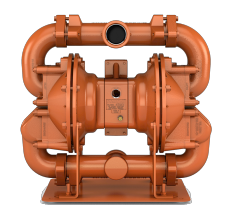

Wilden Pump & Engineering LLC has been the market-leading manufacturer of air-operated diaphragm pumps since 1955 when Jim Wilden founded his company to produce the pump he had invented. Wilden is now the pioneer in pump technology, constantly striving to lead innovation, resulting in an unparalleled breadth, quality, and performance in their product lineup. Wilden caters to the pump needs across most process industries.

In the 2000s, Wilden expanded its horizons and started manufacturing various other pump technologies. Today, they produce centrifugal pumps following the acquisition of Griswold and internal gear pumps following the acquisition of a seal-less magnetically coupled gear pump called EnviroGear. EnviroGear was developed by an engineering company in Chicago named PeopleFlo, specializing solely in product development.

Why buy from AxFlow

AxFlow offers fluid handling equipment for the widest range of industries and applications. Only at AxFlow do you receive individual advice from industry-experienced process engineers and the selection of the world's leading process technology equipment. Do you need support in selecting the right pump for your needs? Do not hesitate to get in touch. AxFlow's experts and engineers can provide guidance for selecting, specifying, installing, and maintaining your pump

The wide range of Wilden series that include different constituting materials and series means that they are applicable across many different industries and areas of application. Some of these industries are food & beverages, water & waste water handling, and pharmaceutical industries.

There are several series in the Wilden catalogue that are developed specifically for sanitary and hygienic purposes.

where can i buy Wilden PUmp Accessories?

The Wilden line of pump accessories enhance and protect your liquid process as well as add value to it. Whether you need a surge dampener to minimize pressure fluctuation, or an electronic controller to automate your pumping process, these accessories allow your Wilden pump to easily adapt to your specific application environment.

One of the main pros of wilden pumps is that they can run dry for an extended period of time without any damage to the pump or parts of it.

Contact us at AxFlow to learn more about the Wilden pumps portfolio.