PUMPS FOR YOUR BREWERY PROCESS

Industrial pumps in beer production demand fundamentally different requirements. From wort dosing and filtration to wastewater treatment and filling, each process has its suitable pump technology for perfect hygiene, precise and gentle dosing, and high energy efficiency.

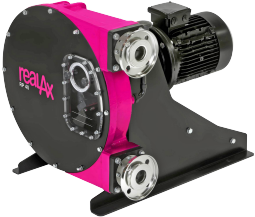

HOSE PUMPS FOR FILTRATION WITH DIATOMACEOUS EARTH, PVPP, AND SILICA GEL

realAx's high-pressure hose pumps are self-priming and run dry. The multiply reinforced hose reliably withstands abrasive media while maintaining the porous surface structure of the diatomaceous earth.

- Ideal for filtration with diatomaceous earth, PVPP, silica gel

- Perfect for the gentle dosing of wort

- Ideal for yeast harvesting in fermentation tanks

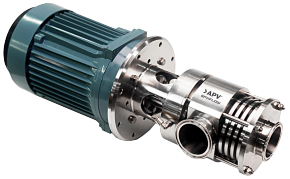

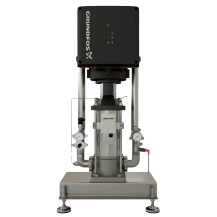

HYGIENIC PUMPS FOR BREWHOUSE AND COLD PROCESS

APV's stainless steel pumps, with EHEDG, 3A, and EU1935/2004 certifications, are designed for efficient CIP cleaning. From the drive to the impeller, all components promise high efficiency and optimal energy efficiency.

- Ideal for CIP cleaning processes

- Perfect for supply to filling

- Available directly from AxFlow's central warehouse

HOSES FOR HOSE PUMPS

Ovatio's replacement hoses. Suitable for hose pumps from all leading manufacturers and available in different materials. Food-grade hoses for your hose pump are available in many sizes directly from stock and at favorable terms.

- High resistance, long service life

- Available with FDA, EU1935/2004 food certifications

- For hose pumps from major manufacturers, a wide selection directly from stock is available

VALVES FOR INTELLIGENT PROCESS CONTROL

Hygienic double-seat valves, shut-off valves, control units, and other valve technologies from APV ensure the safe separation of cleaning and product liquids.

- Secure separation of CIP and product flows

- Balanced construction withstands pressure spikes.

- Valves and spare parts available directly from stock

HYGIENIC HEAT EXCHANGERS

APV's gasketed plate heat exchangers with stainless steel frames are flexibly expandable and available with food-safe double walls and hygiene certificates.

- Ideal as wort coolers in brewery processes

- Unique plate structures prevent fouling

- Efficient heat recovery with high efficiency

REPAIR, MAINTENANCE, ASSEMBLY

Our service technicians are here for you – on-site at your facility or in our service workshops. We support you in the assembly, commissioning, maintenance, and repair of pumps, valves, heat exchangers, and mixing technology.

- Comprehensive service for hygiene processes

- Experienced AxFlow service technicians and workshops

- Optimized system efficiency and safety for your operation

DIRECTLY FROM STOCK WITH EXPRESS SHIPPING

Our AxFlow central warehouse constantly stocks all essential spare parts as well as pumps, valves, and mixers. A new pump hose, a heat exchanger plate, or a membrane kit will reach you via express shipping.

- Continuous stock of pumps, valves, mixers, and spare parts

- Direct product availability with express shipping

- Pre-assembly and individual conversion possible