Dairy Industry Challenges and Fluid Handling Solutions

The dairy industry heavily relies on efficient fluid handling solutions to maintain product quality and integrity throughout various production processes. AxFlow offers specialized equipment tailored for diverse applications in dairy production.

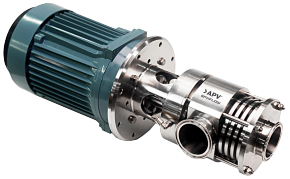

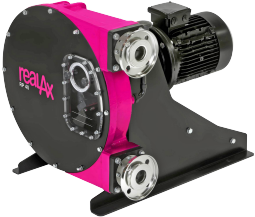

Pumps for Precise Liquid Transfer

Pumps play a pivotal role in dairy operations, from delicate milk transfer to handling viscous cream and curd. AxFlow provides an array of pumps tailored for dairy applications, ensuring the gentle conveyance of sensitive dairy products. Our pumps, such as peristaltic pumps, lobe pumps, AODD pumps, Circumferential piston pumps and centrifugal pumps, maintain the integrity of dairy products throughout processing, ensuring efficient and hygienic liquid transfer.

Valves Ensuring Hygiene and Control

Hygienic valves are crucial in dairy processing, controlling the flow of liquids with precision while maintaining strict hygiene standards. AxFlow offers specialized valves designed for dairy applications, ensuring product integrity and adherence to stringent hygiene regulations.

Vacuum Pumps for Dehydration and Evaporation

Vacuum technology plays a vital role in dehydration, evaporation, and concentration processes within dairy production. AxFlow's range of vacuum pumps ensures efficient and reliable operations, maintaining the quality of dairy products by controlling temperature and reducing moisture content.

Heat Exchangers for Temperature Control

Precise temperature control is essential in dairy processing to maintain product consistency and quality. AxFlow's heat exchangers, such as plate heat exchangers, ensure accurate temperature regulation during pasteurization, sterilization, and cooling processes, preserving the nutritional value of dairy products while meeting stringent hygiene standards.

Mixers for Homogeneous Blending

Homogeneous blending is crucial in dairy production to ensure uniformity in product composition. AxFlow's mixers, including static mixers and dynamic mixers, facilitate consistent blending of ingredients, ensuring the quality and consistency of dairy products.

Partnering with AxFlow in the Dairy Industry

AxFlow goes beyond providing equipment; we aim to collaborate with dairy manufacturers, offering expertise and tailored solutions to optimize fluid handling processes. Our team of experts provides consultation, specifications, and ongoing support to ensure seamless operations and superior dairy production.

Elevate Your Dairy Processing with AxFlow

Partner with AxFlow to enhance your dairy processing operations. Our expertise coupled with top-of-the-line fluid handling equipment guarantees precision, reliability, and adherence to the highest hygiene standards. Let us support your journey in producing dairy products of exceptional quality.

For inquiries, consultations, and customized fluid handling solutions tailored to meet your dairy industry requirements, connect with AxFlow today. Let us collaborate to refine and elevate your dairy production processes to new levels of excellence.