How do Hygienic centrifugal pumps work?

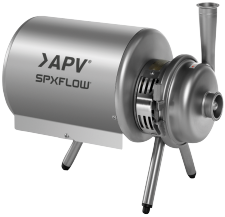

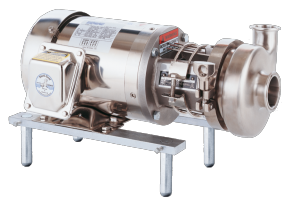

Hygienic centrifugal pumps are a type of pumps that is widely used in the food, beverage, and pharmaceutical industries to transfer liquids in a hygienic manner. These pumps are designed to meet the strict hygienic requirements of these industries and are made of materials that are easy to clean and sterilize.

Hygienic centrifugal pumps are a type of pumps that is widely used in the food, beverage, and pharmaceutical industries to transfer liquids in a hygienic manner. These pumps are designed to meet the strict hygienic requirements of these industries and are made of materials that are easy to clean and sterilize.

The basic principle of a hygienic centrifugal pump is the conversion of mechanical energy into hydraulic energy. The pump uses an impeller to create a centrifugal force that increases the velocity of the fluid and transfers it through the pump's discharge outlet. The impeller is driven by a motor that is coupled to the pump's shaft.

The basic principle of a hygienic centrifugal pump is the conversion of mechanical energy into hydraulic energy. The pump uses an impeller to create a centrifugal force that increases the velocity of the fluid and transfers it through the pump's discharge outlet. The impeller is driven by a motor that is coupled to the pump's shaft.

When the pump is switched on, the fluid is drawn into the pump's inlet and enters the impeller. As the impeller spins, it forces the fluid outwards, creating a high-pressure zone near the center of the impeller and a low-pressure zone at the outer edges. This pressure differential causes the fluid to move towards the pump's discharge outlet, where it is expelled.

Hygienic centrifugal pumps are designed to be highly efficient and reliable, with minimal maintenance required. They are also designed to be easily disassembled for cleaning and sterilization, and to minimize the risk of contamination. In addition, these pumps are often equipped with features such as seals and impellers that are specifically designed to handle abrasive or viscous fluids.

Hygienic centrifugal pumps are designed to be highly efficient and reliable, with minimal maintenance required. They are also designed to be easily disassembled for cleaning and sterilization, and to minimize the risk of contamination. In addition, these pumps are often equipped with features such as seals and impellers that are specifically designed to handle abrasive or viscous fluids.

Advantages of Hygienic centrifugal pumps

Hygienic centrifugal pumps offer numerous advantages over other types of pumps in hygienic applications, particularly in the food and pharmaceutical industries.

- High Efficiency: centrifugal pumps are designed with a high level of efficiency, typically in the range of 50-90%, which means they require less energy to operate than other types of pumps. This efficiency can also be fond in the hygienic version centrifugal pumps

- Hygienic Design: hygienic centrifugal pumps are designed to meet strict hygienic standards, which is essential for food and pharmaceutical applications. They are typically made of high-quality stainless steel and feature a smooth, polished finish that is easy to clean and sanitize.

- CIP Capability: hygienic centrifugal pumps are typically designed for Clean-in-Place (CIP) operations, which allows for easy cleaning and maintenance without disassembly. This helps to minimize downtime and reduce the risk of contamination.

Industries and applications that use Hygienic centrifugal pumps

Industries that require the transfer of fluids while maintaining a high level of hygiene and cleanliness often turn to hygienic centrifugal pumps for their needs. These pumps are extensively used in a range of fields, including food and beverage, pharmaceutical, biotechnology, and chemical manufacturing.

Industries that require the transfer of fluids while maintaining a high level of hygiene and cleanliness often turn to hygienic centrifugal pumps for their needs. These pumps are extensively used in a range of fields, including food and beverage, pharmaceutical, biotechnology, and chemical manufacturing.

In the food and beverage industry, hygienic centrifugal pumps are a preferred choice for the transfer of liquid food products like milk, juices, and syrups. In the pharmaceutical industry, where the manufacturing process requires high levels of hygiene and cleanliness, these pumps are the ideal option for transferring liquids.

In the food and beverage industry, hygienic centrifugal pumps are a preferred choice for the transfer of liquid food products like milk, juices, and syrups. In the pharmaceutical industry, where the manufacturing process requires high levels of hygiene and cleanliness, these pumps are the ideal option for transferring liquids.

Biotechnology companies also rely on Hygienic centrifugal pumps for the transfer of fluids used in the manufacturing of biopharmaceutical products.

The chemical industry also benefits from the use of hygienic centrifugal pumps, particularly for the transfer of chemicals that require a high level of hygiene and cleanliness, such as those used in the production of cosmetics and toiletries. Overall, these pumps provide a reliable and efficient solution for industries that demand strict hygiene and cleanliness standards.

The chemical industry also benefits from the use of hygienic centrifugal pumps, particularly for the transfer of chemicals that require a high level of hygiene and cleanliness, such as those used in the production of cosmetics and toiletries. Overall, these pumps provide a reliable and efficient solution for industries that demand strict hygiene and cleanliness standards.

Important considerations wheN selecting Hygienic centrifugal pumps

When selecting a hygienic centrifugal pump, there are several important considerations to keep in mind. These include:

- Hygienic Design: It is essential to select pumps with a hygienic design that can be easily disassembled, cleaned, and sanitized to prevent contamination.

- Material of Construction: The pump materials must be compatible with the fluid being pumped, and they should also be corrosion-resistant and easy to clean.

- Flow Rate and Pressure: The flow rate and pressure requirements of the application must be considered to ensure that the pump can meet the demands of the process.

- Efficiency: Selecting an efficient pump can reduce energy costs and lower the carbon footprint of the process.

- Maintenance and Serviceability: The pump must be easy to maintain and service, with readily available spare parts and service support.

- Regulatory Compliance: The pump should comply with relevant industry standards, regulations, and certifications to ensure safe and reliable operation.

Why buy Hygienic centrifugal pumps from AxFlow?

AxFlow provides Hygienic centrifugal pumps that cater to an extensive variety of industries and applications. Exclusive to AxFlow, you will be provided with personalized recommendations from highly experienced process engineers, and access to the most prominent process technology manufacturers that are independent of the manufacturer. If you require assistance in selecting the appropriate pumps that satisfy your requirements, feel free to contact AxFlow without any delay. AxFlows engineers and specialists can help with the selection process, specifications, installation, and maintenance of your fluid handling equipment.

AxFlow provides Hygienic centrifugal pumps that cater to an extensive variety of industries and applications. Exclusive to AxFlow, you will be provided with personalized recommendations from highly experienced process engineers, and access to the most prominent process technology manufacturers that are independent of the manufacturer. If you require assistance in selecting the appropriate pumps that satisfy your requirements, feel free to contact AxFlow without any delay. AxFlows engineers and specialists can help with the selection process, specifications, installation, and maintenance of your fluid handling equipment.