What makes a peristaltic pump hygienic?

Hygienic peristaltic pumps are positive displacement pumps used in the food, pharmaceutical, and biotech industries to transfer sensitive and viscous fluids. They operate using a peristaltic principle, where a flexible tube is compressed by a series of rollers or shoes, creating a vacuum that draws in fluid and then propels it through the tube.

Hygienic peristaltic pumps are positive displacement pumps used in the food, pharmaceutical, and biotech industries to transfer sensitive and viscous fluids. They operate using a peristaltic principle, where a flexible tube is compressed by a series of rollers or shoes, creating a vacuum that draws in fluid and then propels it through the tube.

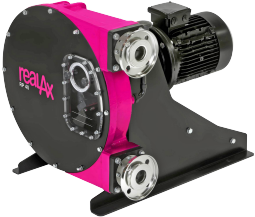

Hygienic peristaltic pumps consist of several components, including the pump head, tubing, rollers or shoes, and motor. The pump head houses the flexible tubing, which is made from materials such as silicone, EPDM, or PTFE, depending on the fluid being pumped. The rollers or shoes compress the tubing, creating a vacuum that draws in fluid, and then propel the fluid through the tubing. The motor drives the rollers or shoes to compress the tubing and move fluid through the pump.

Hygienic peristaltic pumps have several advantages over other types of pumps. For instance, they provide gentle fluid handling, making them ideal for handling shear-sensitive and viscous fluids. They are also designed for easy cleaning and sanitization, with smooth surfaces and removable pump heads. Additionally, they offer accurate flow control that can be easily adjusted by changing the speed of the motor or the size of the tubing.

Hygienic peristaltic pumps have several advantages over other types of pumps. For instance, they provide gentle fluid handling, making them ideal for handling shear-sensitive and viscous fluids. They are also designed for easy cleaning and sanitization, with smooth surfaces and removable pump heads. Additionally, they offer accurate flow control that can be easily adjusted by changing the speed of the motor or the size of the tubing.

Hygienic peristaltic pumps come in a range of sizes and capacities to suit different applications. For example, smaller pumps may have flow rates of around 0.1 to 2.0 liters per minute, while larger pumps can handle flow rates of up to 100 liters per minute or more. They can also handle a wide range of viscosities, from low-viscosity liquids to highly viscous fluids with viscosities of up to 50,000 cP or more.

Features and advantages of hygienic peristaltic pumps

Hygienic peristaltic pumps are a popular choice in industries such as food, pharmaceuticals, and biotechnology due to their unique features and advantages. Here are some of their key features and advantages:

- Gentle Fluid Handling: Hygienic peristaltic pumps provide gentle fluid handling, making them ideal for handling shear-sensitive and viscous fluids that may be damaged by other types of pumps. They operate by compressing a flexible tube, which minimizes the risk of damage to the fluid being pumped.

- Accurate Flow Control: Hygienic peristaltic pumps provide accurate flow control, which is critical in industries that require precise dosing or metering of fluids. Flow rates can be easily adjusted by changing the speed of the motor or the size of the tubing.

- Versatility: Hygienic peristaltic pumps are highly versatile and can handle a wide range of fluids, from low-viscosity liquids to highly viscous fluids with viscosities up to 50,000 cP or more. They are also available in a range of sizes and capacities to suit different applications.

Industries and applications that use hygienic peristaltic pumps

Hygienic peristaltic pumps are highly versatile and find applications in a diverse range of industries that involve the transfer of sensitive and viscous fluids. One such industry is the food and beverage sector where these pumps are commonly used to transfer liquid food products like fruit juices, dairy products, and sauces. Additionally, the beer and wine industry also employs peristaltic pumps to transfer liquid ingredients during the brewing and fermentation processes.

The pharmaceutical industry also makes extensive use of hygienic peristaltic pumps to handle sensitive and viscous fluids like vaccines, blood products, and cell cultures. These pumps are designed to comply with strict FDA regulations and GMP guidelines. Similarly, in the biotech industry, peristaltic pumps are used to handle shear-sensitive fluids like cell cultures, fermentation broths, and enzymes, ensuring the final product's integrity.

In the chemical industry, corrosive, abrasive, and hazardous fluids like acids, bases, and solvents are commonly transferred using peristaltic pumps. These pumps are engineered to resist the corrosive effects of such fluids and guarantee operator safety. Meanwhile, in the water treatment industry, peristaltic pumps are used to transfer chemicals like chlorine and fluoride, ensuring accurate dosing while handling the corrosive nature of these substances.

Finally, in the cosmetics industry, hygienic peristaltic pumps are used to transfer viscous fluids such as lotions, creams, and shampoos, providing precise dosing while handling the high viscosity of these products. Overall, peristaltic pumps' advantages make them an excellent choice for handling sensitive and viscous fluids in diverse industries.

Important considerations when selecting hygienic peristaltic pumps

Selecting the right hygienic peristaltic pump requires careful consideration of several factors, including the following:

- Viscosity: Peristaltic pumps are ideal for transferring viscous fluids, but the pump's design and tubing must be selected to match the fluid's viscosity. Higher viscosity fluids may require a larger pump head or tubing with a larger diameter to prevent clogging or damage to the pump.

- Sterilization: Sanitation is critical in many industries like food and pharmaceuticals. Hygienic peristaltic pumps use hose replacement as it’s cleaning process. This is a fast and easy process which results in a new uncontaminated hose and very little downtime.

- Material Compatibility: The material compatibility of the pump's tubing is essential when selecting a peristaltic pump. The tubing must be resistant to the fluid being transferred to prevent damage or contamination. Different tubing materials such as silicone, EPDM, and Tygon are available, and the choice will depend on the application requirements.

- Maintenance: The maintenance requirements of the pump must be considered when selecting a peristaltic pump. Some pumps require frequent tube changes, while others can go months or years without needing maintenance.

Why buy hygienic peristaltic pumps from AxFlow?

AxFlow provides hygienic peristaltic pumps that cater to an extensive variety of industries and applications. Exclusive to AxFlow, you will be provided with personalized recommendations from highly experienced process engineers, and access to the most prominent process technology manufacturers that are independent of the manufacturer. If you require assistance in selecting the appropriate pumps that satisfy your requirements, feel free to contact AxFlow without any delay. AxFlow's engineers and specialists can help with the selection process, specifications, installation, and maintenance of your fluid handling equipment.