Challenges in Pumping Latex

Pumping latex, a non-Newtonian fluid known for its extreme shear sensitivity, presents a set of intricate challenges. Managing this unique substance demands specialized techniques to ensure its integrity and effectiveness during the pumping process.

- Shear Sensitivity: Latex emulsions are highly shear-sensitive, requiring pumps that can consistently deliver a low shear rate. Excessive shear can alter the latex's structure, affecting its properties and functionality.

- Air Contact Prevention: Any contact with air can lead to the polymerization of latex, necessitating careful attention to seal arrangements. Proper sealing mechanisms are crucial to prevent air exposure and maintain the latex's stability.

- Handling Varying Viscosities: Latex can exhibit varying viscosities, making it essential to employ pumps capable of handling liquids with different thickness levels efficiently and consistently.

- Cleanability and Maintenance: Ensuring easy cleanability and maintenance is vital when dealing with latex. Pumps should be designed for effortless disassembly and cleaning, preventing residual buildup and ensuring consistent performance over time.

Handling Latex

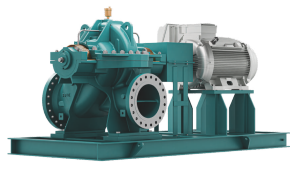

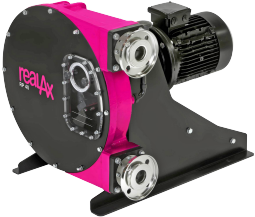

- Low Shear Pumping Actions: AxFlow UK offers a range of technologies with low shear pumping actions, preserving the latex's structural integrity throughout the pumping process.

- Sealless or Double Mechanical Seals: AxFlow provides pumps that are either sealless or can be fitted with double mechanical seals, ensuring airtight operation and preventing latex exposure to the external environment.

Examples of Latex and Latex Related Applications

- Latex Paints: Used in the construction industry and home décor for smooth and even finishes.

- Medical Gloves: Latex gloves widely used in healthcare settings for hygiene and safety.

- Textile Industry: Latex utilized for fabric coatings, adhesives, and waterproofing treatments.

- Balloon Production: Latex balloons for various events and celebrations.

- Dental Devices: Latex-based products like dental dams used in dental procedures.

Pumping latex requires a delicate balance of expertise and technology. AxFlow UK's array of low shear pumping solutions, sealless or fitted with double mechanical seals, ensures the seamless handling of latex. By addressing the complexities associated with latex, AxFlow guarantees the preservation of its properties and functionality, setting new standards in latex pumping technology.

Why Buy From AxFlow

AxFlow UK offers a range of technologies with low shear pumping actions and that are either sealess or can be fitted with double mechanical seals.