Progressive cavity, Helical rotor pumps

Progressive Cavity Pumps

7 series from 1 manufacturers

-

- Booster

- Circulation

- Cleaning

- Control

- Conveying

- Cooling

- Descaling

- Desinfection

- Dewatering

- Diagnostic

- Discharge

- Distribution

- Dosing

- Drain

- Drainage

- Dredging

- Extraction

- Feed

- Filling

- Filtration

- Flow Control

- Handling

- Heating

- High-Pressure

- High-Temperature

- High-Volume

- Injection

- Irrigation

- Level Control

- Lift

- Lifting

- Loading

- Low-Pressure

- Lubrication

- Medium-Pressure

- Metering

- Mixing

- Off-loading

- Pressurisation

- Process

- Processing

- Recirculation

- Recovery

- Refueling

- Replacement

- Rinsing

- Sampling

- Settling

- Spraying

- Tempering

- Transfer

- Treatment

- Unloading

- Volumetric Dispensing

- Washing

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Alcohols

- Aluminium Oxide Slurry

- Ammonia

- Beer

- Biological Broths and Slurries

- Bitumen

- Carbon Fibers

- Caustic Solutions

- Cereals

- China Clay Slurry

- Chocolate

- Clay

- Coffee

- Concrete

- Cooling Water

- Corrosive Dyes

- Corrosive Liquids

- Cryogenic Liquids

- Crystalline Slurry

- Dairy Products

- Detergents

- Diesel Fuel Oil

- Drinking Water

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Fertilizers

- Foam Protein

- Fruit and Vegetables

- Fruit Concentrates

- Gels

- Glycol

- High Viscosity Liquids

- HydrochloricAcid

- Irrigation Water

- Lake Water

- Latex

- Light Fluids

- Lime

- Low NPSH

- Low Viscosity Liquids

- LPG

- Meat

- Milk

- Molasses and Syrups

- Must

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Pet Food

- Phosphoric Acid

- Plastic

- Process Condensate

- Produced Water

- Radio Active Fluids

- Redox

- Refrigerants

- Rubber

- Sauces

- Seawater

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Sewage

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Spirits

- Sulphuric Acids

- Surface Water

- Surfactants

- Synthetic Fibers

- Thermal Oil

- Thin Liquids

- Thixotropic Fluids

- Toxic Liquids

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Wastewater

- Water

- Water Hardness

- Wine

- Wort

-

- Abrasion Resistant

- Adjustable-Flow

- Automatic

- Booster Sets

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Containment

- Corrosion-Proof

- Direct-Drive

- Electric

- Explosion-Proof

- Fish Friendly

- Flange

- Heavy-Duty

- High System Pressure

- High Temperature

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- In-Line

- Intrinsically Safe

- Low Shear

- Low-Noise

- Mechanical

- Mechanical Seal

- Mixed Flow

- Mobile

- Modular

- Motorless

- Multi-Stage

- Oil-Free

- Pulse-less

- Rotary

- Rugged

- Sanitary

- Seal-less

- Self-priming

- Single-Stage

- SIP

- Solids Handling

- Variable Speed

- Vertical

- Vertical-Mount

HOW DO PROGRESSIVE CAVITY PUMPS WORK?

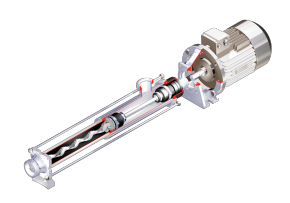

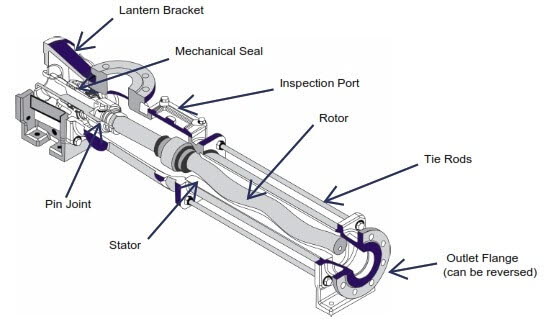

Progressive cavity pumps, also known as PC pumps, eccentric screw pumps and helical rotor pumps, are a type of positive displacement pump. A spiral helical rotor similar to a corkscrew sit within the stator and as it rotates cavities are formed through which the fluid moves. The cavities have a specific volume that decides the volumetric flow rate of the pump and is directly proportional to the rotational speed of the rotor, resulting in a low amount of shearing and little to no pulse. The size of the pump and the fluid being pumped usually determines the rotational speed of the pump. Larger pumps tend to run at lower RPMs while smaller pumps tend to run at higher RPMs. With a gearbox or rubber v-belts between the pump and motor the speed of the pump can be controlled.

A Progressive Cavity Pump is a positive displacement pump, consisting of a stator & rotor designed to handle viscous, abrasive, and shear-sensitive fluids. The metal rotor drives the stator through the chain and begins to fill the cavities with an equal amount of liquid which then flows through the pump outlet. They are a highly robust pumping system that ensures optimum performance and reliability which allows for the ability to provide a smooth and pulsation-free flow, making them suitable for a wide range of applications across various industries.

ADVANTAGES OF PROGRESSIVE CAVITY PUMPS

Economical: Progressive cavity pumps are often more efficient in the long run as they require minimum maintenance. Other pump types that provide a faster flow rate may encounter maintenance concerns in applications with high viscosity or temperature sensitive materials. If or when maintenance is needed for progressive cavity pumps, it can usually be performed on-site.

Flow: PC pumps both create a constant flow and a smooth, low pulsation, flow. The gentle pumping action combined with large continuous cavities ensures low shear. This allows suspended solids to be handled with ease, resulting in delicate solids or fluids not being damaged in the process. Thanks to the constant and low pulsation flow, the pump type can also be used for precise dosing.

Pressure: PC pumps can both achieve and handle high pressure, making the pumps efficient at pumping fluid over longer distances, thus eliminating the need for multiple pumps.

Running speed: As the speed of the pump can be controlled, regulating flow is simple. As the pump can be run at low speeds, it is particularly suitable for abrasive applications.

Difficult fluids handling: Progressive cavity pumps may sometimes be overlooked as they are typically more efficient when operating at lower speeds. However, viscous, abrasive, and temperature-sensitive materials can cause problems in other pump types with higher flow rates. Thanks to the low internal speed and high-pressure capabilities of progressive cavity pumps, they can handle difficult fluids such as viscous and abrasive fluids resulting in less wear and tear from fluid particles.

Self-Priming: Progressive Cavity pumps tend to also be self-priming and tend to not vapor lock.

The downsides of progressive cavity pumps are that they cannot be dry-run or pump against a closed discharge as this would likely damage the pump.

Cavity pump APPLICATIONS

Progressive cavity pumps tend to be utilised in order to pump fluids that cannot typically be handled by other industrial pumps, and are especially suited when a fluid needs to be handled gently, contain solids, and/or have high viscosity.

Other areas and industries where progressive cavity pumps are well suited include:

- Pumping, dosing, and metering chemicals where accuracy is required.

- Hygienic environments and/or shear sensitive fluids such as in the food, drink and cosmetics industry.

- Pumping materials that contain abrasive particles such as wastewater management and pumping sewage, sludge or slurry.

- Pumping heavy or viscous fluids such as oil and chemicals.

- Applications that require varied flow rates.

IMPORTANT CONSIDERATIONS WHEN SELECTING THE RIGHT PUMP

Progressing cavity pumps differ fundamentally from one another depending on the industrial application. The components are available in different materials and designs to best suit the specific application or fluid requirements.

The three key considerations when selecting a progressive cavity pump are:

Viscosity: The more viscous a fluid is, the lower the operating speed of the pump should be. The efficiency of progressive cavity pumps is highest at slower speeds. In order to maximise resistance to wear, it is ideal to select a design which keeps the linear fluid velocity at less than seven feet per second. However, solids can fall out of suspension at velocities less than four feet per second.

Temperature: Stator material must correlate with the fluid temperature. The size of the pump is also key as increases in fluid temperature will result in the expansion of the elastomer stator. Another important consideration is the application and fluid have significant temperature variations, progressing cavity pumps is often not the most suitable solution.

Abrasiveness: The higher the abrasive properties of the fluid the better to select a larger pump and run it at slower speeds rather than selecting a smaller, faster, pump. This may seem more expensive, but it is likely to improve the return on investment and in the long-term reduce maintenance costs. It is recommended that the pressure per stage be lowered if abrasive fluids are to be pumped.

WHY BUY PROGRESSIVE CAVITY PUMPS FROM AXFLOW

AxFlow UK represents Mono progressive cavity pumps that have over 70 years experience.The progressive cavity pump principle is ideal for handling liquids that can be slurries, viscous, shear sensitive, 2 or 3 phase mixtures or when applications require, significant suction lift capabilities. The heart of the Progressive Cavity pump is the rotor and stator. As the single helix rotor revolves eccentrically within the double helix of the stator, a continuous cavity is formed and progresses towards the discharge end of the pump as the rotor rotates

Progressive Cavity Pump Maintenance

It is ideal to check a progressive cavity pump for wear after roughly 700-1000 operating hours. The frequency of subsequent inspections is determined in relation to the degree of wear noted. It is suggested that the interval between inspections must however, not surpass 1500 operating hours.

Cleaning Progressive Cavity Pumps:

- Through the cleaning ports in the pump housing

- Manually after dismantling the PC pump

The rotating parts of a pump tend to wear down overtime, which means that they typically need to either be exchanged or readjusted. Technological innovations haved allowed for quicker and easier access to the rotor and stator unit and even ways to readjust them for increased flow.

However, pumps with feed hoppers pose a unique challenge. Maintenance on such pumps tends to be rather complex and time consuming as a result of the valves and hoppers obstructing access to the pump.

Maintaining a progressive cavity pump involves several key steps to ensure its optimal performance and longevity. A progressive cavity pump is a type of positive displacement pump commonly used for transferring viscous fluids. Here's a brief overview of the maintenance process:

-

Routine Inspection: Perform regular visual inspections to identify any indications of wear, leakage, or damage. It is recommended to check the stator, rotor, coupling, and other critical components for any abnormalities.

-

Lubrication: Ensure that the pump is properly lubricated to minimize friction and wear between the rotor and stator. Use the recommended lubricants and follow the manufacturer's guidelines. Progressive Cavity Pumps cannot be run dry. However, dry run protection devices for instance, stator temperature probes, can be utilised as well as special sealing configurations which are able to mitigate pump faults from dry-running.

-

Cleanliness: Keep the pump and its surrounding area clean to prevent debris, contaminants, or foreign particles from entering the pump system. This can help prevent clogs and damage.

-

Seal Inspection: Check the seals and gaskets for any indiacations of wear or leaks. Replace them if needed to prevent fluid leakage and maintain efficiency.

-

Fluid Quality: Use the appropriate type of fluid and ensure its quality meets the Cavity pump's specifications. Contaminated or incompatible fluids can lead to performance issues.

-

Vibration and Noise Monitoring: Monitor the pump's vibration and noise levels during operation. Unusual vibrations or increased noise can indicate mechanical issues that need attention.

-

Spare Parts Availability: Keep a stock of key spare parts, such as stators, rotors, seals, and coupling elements, to facilitate quick repairs and minimize downtime.

Remember that specific maintenance requirements can vary based on the pump's design, manufacturer recommendations, and the type of fluid being pumped. Always refer to the manufacturer's documentation and guidelines for detailed maintenance instructions tailored to your specific pump model.