Vertical Axial Flow Pumps flows to 15.000 m3/hr and heads of 10 m

Centrifugal Pumps

75 series from 13 manufacturers

-

- Adhesives

- Agriculture

- Aviation

- Bakery and confectionery

- Beauty & Personal Care

- Brewing and beverages

- Building Services

- Ceramics

- Chemical

- Confectionery

- Convenience food

- Dairy

- Detergents

- Distilleries

- Docks

- Drinking Water

- Fertilizers

- Food & Beverage

- Heating, Water & Sanitation

- Marine

- Meat Processing

- Mining

- Nuclear Power Plants

- Offshore

- Oil & Gas

- Oil Fats & Mayonnaise

- Paints & Resins

- Paper Mills

- Petrochemical

- Pharmaceutical

- Plastic

- Power Generation

- Research & Development

- Surface / Pit

- Surface Finishing

- Textile

- Transportation

- Underground

- Wastewater

- Water Treatment

-

- Analysis

- Booster

- Circulation

- Cleaning

- Control

- Conveying

- Cooling

- Descaling

- Desinfection

- Dewatering

- Diagnostic

- Discharge

- Distribution

- Dosing

- Drain

- Drainage

- Dredging

- Dual Dispensing

- Extraction

- Feed

- Filling

- Filtration

- Flow Control

- Greasing

- Grinding

- Handling

- Heating

- High-Pressure

- High-Temperature

- High-Volume

- Injection

- Irrigation

- Level Control

- Lift

- Lifting

- Loading

- Low-Pressure

- Lubrication

- Medium-Pressure

- Metering

- Mixing

- Off-loading

- Powder Coating

- Pressurisation

- Process

- Processing

- Recirculation

- Recovery

- Refueling

- Replacement

- Rinsing

- Sampling

- Settling

- Spraying

- Tempering

- Transfer

- Treatment

- Ultra High-Pressure

- Unloading

- Volumetric Dispensing

- Washing

- Water-Jet Cleaning

- Water-Jet Cutting

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Alcohols

- Aluminium Oxide Slurry

- Ammonia

- Beer

- Biological Broths and Slurries

- Bitumen

- Carbon Fibers

- Caustic Solutions

- China Clay Slurry

- CIP Fluids

- Clay

- Cooling Water

- Corrosive Dyes

- Corrosive Liquids

- Cryogenic Liquids

- Crystalline Slurry

- Dairy Products

- Detergents

- Diesel Fuel Oil

- Drinking Water

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Ferric Chloride

- Fertilizers

- Foam Protein

- Fruit Concentrates

- Gels

- Glycol

- High Temperature Oils

- HydrochloricAcid

- Irrigation Water

- Lake Water

- Latex

- Light Fluids

- Lime

- Liquid CO2

- Low NPSH

- Low Viscosity Liquids

- LPG

- Milk

- Molasses and Syrups

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Pet Food

- Phosphoric Acid

- Plastic

- Process Condensate

- Produced Water

- Radio Active Fluids

- Redox

- Refrigerants

- Rubber

- Sauces

- Seawater

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Sewage

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Solvents

- Spirits

- Sulphuric Acids

- Surface Water

- Surfactants

- Synthetic Fibers

- Thermal Oil

- Thin Liquids

- Thixotropic Fluids

- Toluene

- Toxic Liquids

- Ultra Pure Water

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Wastewater

- Water

- Water Hardness

-

- Abrasion Resistant

- Adjustable-Flow

- Automatic

- Booster Sets

- Canned

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Containment

- Corrosion-Proof

- Direct-Drive

- Double-Acting

- Electric

- Explosion-Proof

- Flange

- Heavy-Duty

- High System Pressure

- High Temperature

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- In-Line

- Intrinsically Safe

- Low Shear

- Low-Noise

- Magnetic Drive

- Mechanical

- Mechanical Seal

- Mixed Flow

- Mobile

- Modular

- Motorless

- Multi-Stage

- Non-Metal

- Oil-Free

- Plastic Lined

- Pulse-less

- Rotary

- Rugged

- Sanitary

- Seal-less

- Self-priming

- Semi Submersible

- Single-Stage

- SIP

- Solids Handling

- Submersible

- Variable Speed

- Vertical

- Vertical-Mount

Do you need help finding the right pump that meets your needs?

We have experienced experts who are ready to help you!

Get in touch hereWhat are centrifugal pumps

Centrifugal pumps are a type of pump that uses a rotating impeller to increase the velocity of a fluid. The increased velocity results in a flow of fluid in the desired direction. Such pumps are used in a range of different industries for transferring fluids,which may include water, chemicals, and petroleum products.

Centrifugal pumps are the most useful all round pump with a balanced combination of flow and pressure capability. Centrifugal pumps represent approximately 80% of the pumps insalled around the globe.

Why Buy Centrifugal Pumps From AxFlow

With over 80 ranges of centrifugal pumps from 11 different manufacturers, AxFlow is one of the leading suppliers of centrifugal pumps in the UK

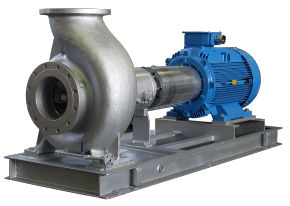

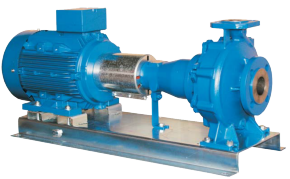

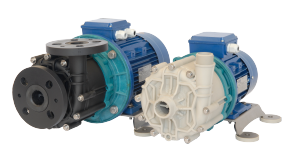

Our range of centrifugal pumps covers almost every type of centrifugal pump that you can think of. This includes DIN pumps, ISO pumps, hygienic centrifugal pumps, API centrifugal pumps, multistage centrifugal pumps, centrifugal pumps that handle solids and canned centrifugal pumps.

With such a large choice of centrifugal pumps we will offer you the most appropriate pump for your application.

Just click on the link....

• DIN 24255 (EN 733) • ISO 5199-2858 • API • ATEX •

• Magnetic Drive • Multistage • Double Suction • Canned • Plastic Lined

• Self Priming • Chemically Resistant • Hygienic • Solids Handling

Our centrifugal pump partners

Gruppo Aturia DIN 2455, ISO 5199, boiler feed, mag drive, API 610, API 685, canned pumps for the nuclear industry, bore hole pumps, APV Hygienic pumps Wernert ISO 5199 lined pumps. Warman Soilds handling pumps Argal Plastic mag drive, plastic mech sealed, plastic column pumps. Waukesha Hygienic pumps. Hermetic Canned pumps. Hayward Gordon Soilds handling pumps. Finder API 610 pumps. Varisco Industrial self priming pumps. Bungartz Specialist low NPSHa pumps.

Where can centrifugal pumps be used

Centrifugal pumps are utilised through a variety of different industries as a result of their efficiency and versatillity.

They tend to be used in the transfer of low viscosity fluids, with some of the main applications where centrifugal pumps are used include water supply and distribution systems, wastewater treatment plants as well as oil and gas, chemical processing, power generation, and food and beverage production. Centrifugal pumps tend to be ideal for processes that require a continuous and steady flow of fluids, making them a essential in a range of different processes across varyingsectors.

How to Select a Centrifugal Pump

Selecting the correct centrifugal pump is critical to achieving reliable operation, high efficiency, and long service life. Proper selection requires careful evaluation of hydraulic requirements, fluid properties, mechanical design, materials, and control methods to ensure the pump operates close to its design point under all operating conditions.

1. Define Hydraulic Requirements

Flow Rate (Q)

The required flow rate is the primary sizing parameter and must be determined from system demand, expressed in m³/h, L/s, or GPM. Oversizing increases energy consumption and operating costs, while undersizing limits system performance.

Total Dynamic Head (TDH)

Calculate Total Dynamic Head as the sum of:

- Static suction and discharge head

- Friction losses in piping

- Minor losses from valves, fittings, and heat exchangers

The selected pump should operate near its Best Efficiency Point (BEP) at the required flow and head to minimise vibration, hydraulic instability, and wear.

Net Positive Suction Head (NPSH)

Ensure NPSH Available (NPSHa) exceeds NPSH Required (NPSHr) with an adequate margin to prevent cavitation. Consider suction piping layout, fluid temperature, vapor pressure, and elevation.

2. Evaluate Fluid Properties

Fluid Type

Clean liquids, hydrocarbons, slurries, or chemical solutions directly influence pump hydraulics, sealing, and materials.

Density and Viscosity

- Increased density raises shaft power requirements

- High viscosity reduces efficiency and alters pump curves

Viscosity corrections may be required for non-Newtonian or heavy fluids.

Temperature

Elevated temperatures affect:

- Mechanical seal selection

- Bearing lubrication

- Thermal growth and clearances

Solids Content

For fluids containing abrasives or suspended solids, select:

- Open or semi-open impellers

- Hardened materials or wear coatings

- Reduced operating speeds

3. Select Pump Type and Configuration

Common centrifugal pump types include:

- End-suction pumps for general industrial service

- Split-case pumps for high flow and continuous duty

- Vertical inline pumps for space-restricted installations

- Multistage pumps for high-pressure applications

Installation Layout

- Horizontal pumps offer easy maintenance access

- Vertical pumps suit sumps, pits, and limited floor space

Centrifugal Pump Maintenance Best Practices

Proper centrifugal pump maintenance is critical for sustaining hydraulic efficiency, preventing cavitation, and extending equipment life. Pumps operating away from their Best Efficiency Point (BEP) experience increased vibration, seal failure, and accelerated bearing wear. A structured maintenance programme reduces downtime and lifecycle costs.

Routine Inspection and Monitoring

- Inspect for leakage at mechanical seals, packed glands, casing joints, and flanges

- Monitor vibration, noise, bearing temperature, and motor load

- Record flow rate, discharge pressure, and power consumption to detect hydraulic degradation

- Trend performance data against pump curves and baseline readings

Bearings, Lubrication, and Alignment

- Maintain correct lubricant type, quantity, and change intervals

- Avoid over-greasing; monitor oil condition in oil-lubricated systems

- Rising temperature or vibration indicates bearing wear or lubrication failure

- Verify pump-to-motor alignment after installation, overhaul, or thermal changes

- Inspect flexible couplings for wear or elastomer degradation

Impellers, Clearances, and Hydraulics

- Inspect impellers for erosion, corrosion, cavitation, or solids buildup

- Measure wear ring and internal clearances against manufacturer tolerances

- Excessive clearances reduce efficiency and increase axial and radial loads

- Clean or recondition imbalanced or damaged impellers

Mechanical Seals and Packing

- Inspect mechanical seals for leakage, face wear, and elastomer damage

- Ensure seal flush and cooling systems are clean and correctly pressurised

- Maintain controlled leakage in packed glands for lubrication and cooling

- Select seal materials compatible with fluid chemistry and temperature

System and Suction Conditions

- Ensure suction piping is free from restrictions and air ingress

- Maintain adequate NPSH available (NPSHa) to prevent cavitation

- Keep strainers and filters clean to avoid hydraulic instability

Planned Overhaul and Storage

- Schedule overhauls based on operating hours and service severity

- Replace worn bearings, seals, wear rings, and gaskets

- Measure shaft runout and verify alignment before commissioning

- For storage, drain the pump, apply corrosion protection, and rotate shafts periodically

Professional Centrifugal Pump Maintenance & Repair

We provide inspection, condition monitoring, repair, and overhaul services for centrifugal pumps across industrial, water, and process applications.