Why carry out condition monitoring on pumps

Monitoring your pumps is absolutely essential if you want to reduce expensive pump repairs and avoid unexpected pump failures. Monitoring the condition of your pumps will prolong their life, help identify problems somewhere else in your system and reduce your power consumption by keeping them at their optimum efficiency.

AxFlow uk have experienced personnel trained to use the latest condition monitoring equipment with years of pump knowledge.

A range of services that can give you peace of mind to whatever level you require.

- A comprehensive site survey that can include recommendations to optimise your pump running costs.

- Scheduled site visits.

- Vibration tests using the latest equipment.

- Bearing condition measurement.

- Thermal imaging.

- A planned maintenance schedule.

- Onsite training of maintenance operatives.

- Analysis of your liquids with our in-house rheology measuring equipment.

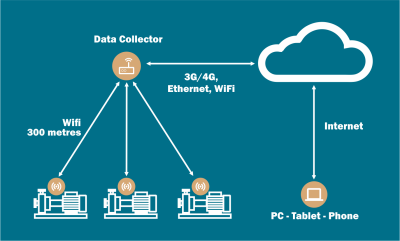

We also offer a state-of-the-art wireless 24/t pump monitoring system that utilises a range of communication methods including 4G.