Air-Operated Double-Diaphragm pumps are a type of positive displacement pump which consists of two pumping chambers that are alternately filled and discharged by the movement of flexible diaphragms. Compressed air is alternately fed to, and vented from, air chambers on the opposite sides of the diaphragms to create the pumping action.

AOD/AODD Pumps

16 series from 2 manufacturers

-

- Analysis

- Booster

- Circulation

- Cleaning

- Control

- Conveying

- Cooling

- Descaling

- Desinfection

- Dewatering

- Diagnostic

- Discharge

- Distribution

- Dosing

- Drain

- Extraction

- Feed

- Filling

- Filtration

- Flow Control

- Handling

- High-Pressure

- High-Temperature

- High-Volume

- Injection

- Irrigation

- Level Control

- Lift

- Lifting

- Loading

- Low-Pressure

- Medium-Pressure

- Metering

- Mixing

- Off-loading

- Powder Coating

- Pressurisation

- Process

- Processing

- Recirculation

- Recovery

- Refueling

- Replacement

- Rinsing

- Sampling

- Settling

- Spraying

- Tempering

- Transfer

- Treatment

- Unloading

- Washing

- Water-Jet Cleaning

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Aluminium Oxide Slurry

- Biological Broths and Slurries

- Caustic Solutions

- China Clay Slurry

- Corrosive Liquids

- Crystalline Slurry

- Dairy Products

- Dye Pigment

- Emulsions

- Ferric Chloride

- Foam Protein

- Fruit Concentrates

- Gels

- HydrochloricAcid

- Latex

- Light Fluids

- Lime

- Low NPSH

- Low Viscosity Liquids

- Milk

- Molasses and Syrups

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Pet Food

- Phosphoric Acid

- Sauces

- Seawater

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Spirits

- Sulphuric Acids

- Surfactants

- Thixotropic Fluids

- Toxic Liquids

- Vegetable Oils

- Viscose

- Viscous Liquids

- Wort

-

- Abrasion Resistant

- Adjustable-Flow

- Automatic

- Booster Sets

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Containment

- Corrosion-Proof

- Direct-Drive

- Double-Acting

- Electric

- Explosion-Proof

- Flange

- Heavy-Duty

- High System Pressure

- High Temperature

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- In-Line

- Intrinsically Safe

- Low Shear

- Low-Noise

- Mechanical

- Mechanical Seal

- Mixed Flow

- Mobile

- Modular

- Motorless

- Multi-Stage

- Non-Metal

- Oil-Free

- Plastic Lined

- Pneumatic

- Pulse-less

- Rotary

- Rugged

- Sanitary

- Seal-less

- Self-priming

- Single-Stage

- SIP

- Solids Handling

- Variable Speed

Do you need help finding the right pump that meets your needs?

We have experienced experts who are ready to help you!

Get in touch here

How does a diaphragm pump work

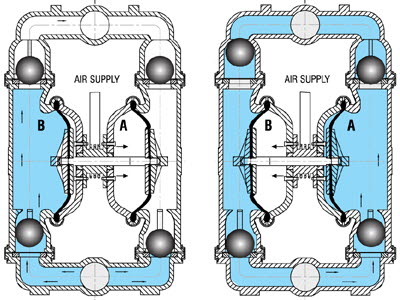

An AODD pump is a positive displacement, reciprocating diaphragm pump powered by compressed air. Instead of a rotating shaft and mechanical seal, it uses two flexible diaphragms connected by a common shaft. An internal air distribution valve (ADV) alternately pressurises one diaphragm chamber while exhausting the other, creating the suction and discharge strokes that move liquid through check valves.

The core components

- Two liquid chambers, each separated from the air side by a diaphragm

- A common diaphragm shaft linking the two diaphragms

- An air distribution valve (spool/slide or poppet style) that routes air alternately to each air chamber

- Inlet and discharge check valves (typically ball, flap or diaphragm check) on each liquid chamber to enforce one-way flow

Step-by-step cycle

-

Air is directed to Chamber A (power stroke)

The ADV sends compressed air behind Diaphragm A, pushing it inward. This reduces the volume of Liquid Chamber A and forces liquid out through its discharge check valve (inlet check closes, discharge check opens). -

Simultaneous suction on Chamber B

Because the diaphragms are linked, Diaphragm B is pulled outward at the same time. The volume in Liquid Chamber B increases, creating suction. Liquid enters through Chamber B’s inlet check valve (discharge check stays closed). -

End-of-stroke valve shift (the “flip”)

As the diaphragms reach the end of travel, a pilot mechanism (mechanical, pneumatic signal, or internal porting depending on the ADV design) triggers the ADV to switch. The previously pressurised air side begins to exhaust. -

Air is directed to Chamber B (power stroke)

Now the ADV pressurises behind Diaphragm B, pushing it inward to discharge liquid from Chamber B while Chamber A refills on suction.

This alternating action produces the characteristic pulsating flow of an AODD pump. Pulsation can be reduced with a pulsation dampener, larger air plumbing, correct suction conditions, and appropriate pump sizing.

When selecting an AODD pump there are a few things to be considered regarding its suitability for application:

- Fluid: The type and composition of the fluid you plan to pump is the most crucial factor. In order to avoid wear and tear or corrosion, determine the fluid’s chemical makeup and consistency, and whether it may be a clean or slurry liquid.

- Viscosity: How viscous a fluid is can be a key factor into the pump selection process. Robust pumping equipment is needed to move highly viscous fluids.

- Pressure: Determining the potential pressure conditions on the inlet and outlet of the pump.

- Temperature: The temperature of the fluid dictates the pump material best suited to a particular application. We offer a wide range of clamped or unclamped plastic and metal Wilden & Almatec AODD pumps enabling you to select the pump best suited to your application.

WHY BUY AODD PUMPS FROM AXFLOW

AxFlow is one of the leading UK suppliers of AODD/AOD pumps with over 50 years of experience. AxFlow UK has a wide range of Air Operated Double Diaphragm pumps from Wilden and Almatec.

Air Operated double diaphragm pumps are widely used for their simple, portable construction and their ability to dry prime, and handle solids.

Air Operated Diaphragm pumps are employed in a host of fluid transfer applications ranging from circulation duties in cleanroom environments to sludge pumping. AODD Pumps are intrinsically safe by design, offering a wide range of material and elastomer options.

Selecting the right AODD pump

Some key considerations for selecting an AODD pump for your application and need include:

- Fluid: Determine the type, composition, and consistency of the fluid you plan to pump to avoid wear and tear or corrosion. Also, consider whether it is a clean or slurry liquid.

- Viscosity: Highly viscous fluids require robust pumping equipment, so factor in the viscosity of the fluid in the pump selection process.

- Pressure: Determine the potential pressure conditions on the inlet and outlet of the pump to ensure that the pump can handle the required pressure.

- Temperature: The temperature of the fluid dictates the pump material best suited to a particular application.

When considering heavy-duty AODD pumps with flap check and ball valves, it is important to evaluate their technical capabilities for efficiency and reliability before making a final decision.

The only significant limitation of AODD pump design is the suction pressure, which is dictated by atmospheric pressure, and can limit performance. To optimize performance, it is best to position the pump as close as possible to the tank or vessel holding the liquid.

Advantages of AODD Pumps

- Are able to run dry for a period of time without damaging costly internal parts.

- Easy to use with a simple design.

- Versatility and the ability to handle a range of viscosities.

Typical applications for AODD pumps

AODD pumps also known as air operated diaphragm pumps, tend to be versatile and find applications in a wide range of industries due to their ability to handle various types of fluids and challenging operating conditions. Here are some common areas where diaphragm pumps can be used:

-

Chemical Industry: Diaphragm pumps tend to be utitlised to transfer and handle a range of chemicals, which includes corrosive and abrasive fluids. They are highly regarded for their ability to handle aggressive substances while maintaining a seal between the fluid and the environment.

-

Pharmaceutical Industry: In the pharmaceutical sector, an AODD pump is employed for transferring sensitive and sterile fluids, including pharmaceutical ingredients, solvents, and purified water, while minimizing the risk of contamination.

-

Food and Beverage Industry: Pneumatic diaphragm pumps are used for transferring food products like sauces, syrups, viscous liquids, and beverages. Their hygienic design and capability to handle a wide range of viscosities make them suitable for these applications.

-

Wastewater Treatment: AOD pumps can handle sludges, slurries, and chemicals in wastewater treatment processes, including dewatering, sludge transfer, and chemical dosing.

-

Paints and Coatings: Air operated diaphragm pumps are employed for transferring paints, coatings, and adhesives due to their ability to handle viscous materials and to provide consistent flow rates.

-

Oil and Gas: AODD pumps find application in the oil and gas sector for transferring crude oil, chemicals, and drilling fluids. Their air-driven operation is advantageous in hazardous or explosive environments.

-

Agriculture: Air operated double diaphragm pump are used for transferring agricultural chemicals, fertilizers, and pesticides in farming applications.

-

Marine Industry: Air operated diaphragm pumps can be useful in the marine industry for transferring bilge water, chemicals, and waste fluids.

In summary, the versatility, reliability, and ability to handle a wide range of fluids and conditions make air operated double diaphragm pumps a valuable tool in many industries where other pump types might struggle, and are utilised for transfer applications, with the ability to handle a range of material such as sludges, slurries, abrasive and shear sensitive fluids. Although they are robust, reliable and easy to maintain they tend to be relatively noisy, prone to icing, and are limited to low pressure applications.

AODD Pump Preventive maintenance procedures may involve:

- Occasionally examining diaphragms for wear and replacing them if necessary: Using a stroke counter is a good way to keep track of approximately how many strokes to expect before a diaphragm needs replacing.

- Reviewing the tightness of the pump’s hardware: This may prevent leakages & damaged seals. Pump hardware generally tends to loosen over time because of temperature changes and vibration. Hardware torque specifications can be found in an operation manual. Tightening hardware when the pump is under pressure is something to avoid.

- Do your research: If you’re relatively new to AODD pumps, researching the performance of pumps in similar applications to yours, may be helpful in getting a rough idea of when your pump may potentially need wet side or air side repairs.

HEAVY-DUTY DESIGN

AxFlow's product range includes heavy-duty AODD pumps, in addition to standard design AOD/AODD pumps, which offer several advantages in handling abrasive slurries, suspended and non-suspended solids, and large-size solids, making them suitable for various industry sectors. The Heavy-Duty Flap Check Valve pumps have a design that optimizes flow capacity, reduces air consumption, ensures continuous performance, and provides minimal flow velocity changes when handling thick and viscous fluids. With their thick walls and large flow area, these pumps prevent solids from settling in the unit. The Heavy-Duty Ball Valve pumps have similar construction but with smaller ports and various discharge porting options. These pumps are suitable for thin to highly viscous and small solids-laden liquids and are designed for use in tight spaces. Finally, the Containment Duty Ball Valve pump has been developed for handling potentially dangerous fluids, preventing leakage, and providing added safety and peace of mind in certain circumstances.