AxFlow are experts in the field of heat exchangers

Heat Exchangers

How do heat exchangers work

Heat exchangers are key in transfer thermal energy between two liquids, without the need of them coming in contact. With a usual heat exchanger, two fluid streams flow in different ways, with the first being hot and the other fluid being cold. As the hot liquid moves through the heat exchanger, it lets out its thermal energy to the walls of the heat exchanger, then conducting the heat to the cold fluid. The cold fluid will then absorb this heat, causing its temperature to increase, while the hot fluid's temperature drops.

This ongoing exchange of thermal energy will then result in the desired heat transfer between the two fluids.

Where can heat exchangers be used

Heat exchangers play a crucial role in a range of processes which includes: HVAC systems, refrigeration, power plants, and industrial processes, enabling energy-efficient heat management and maintaining optimal temperatures in different systems.

Why buy Heat exchangers from AxFlow

AxFlow specialise in the supply of high specification heat exchangers. We offer three very different types of heat exchangers giving us the ability to respond to nearly every application.

We specialize in process heat exchanger solutions for industrial, chemical process and offshore applications along with hygienic food and beverage production.

AxFlow supply a range of different heat exchangers:

Plate Heat Exchanger: widely utilised in industries such as HVAC, food and beverage processing, and automotive applications. Known for their compact footprint and high thermal efficiency, plate heat exchangers are a flexible solution for a variety of duties. Available in gasketed, brazed, and welded formats, they are ideal where space savings, fast heat transfer, and ease of cleaning are priorities.

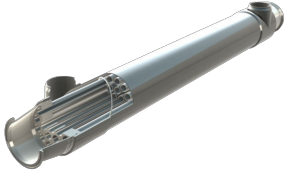

Tube Heat Exchanger: tend to be utilised in applications in power plants, oil refineries, chemical processing, and other industries where higher pressure and temperature conditions are present. They offer a robust and hygienic construction, tube-in-tube and multi-tube designs are widely used in high-pressure or high-temperature environments. They are perfect for applications requiring long service life, minimal maintenance, and the ability to handle particulate-laden or viscous fluids.

Surface scraped heat exchangers: can be utilised in food processing, chemical processing as well as the petrochemical industry, pharmaceutical industry and more. They're known for their compact footprint and high thermal efficiency, plate heat exchangers are a flexible solution for a variety of duties. Available in gasketed, brazed, and welded formats, they are ideal where space savings, fast heat transfer, and ease of cleaning are priorities.

Each system is engineered with process performance, energy efficiency, and product quality in mind, ensuring that our customers receive a solution tailored precisely to their needs. Whether for new installations or system upgrades, AxFlow delivers reliable, cost-effective heat exchanger solutions backed by technical support and decades of experience.

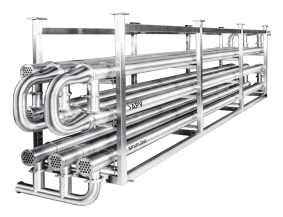

APV Heat Exchangers

APV heat exchangers have a proven track record of phenomenal reliability, performance, and quality, thus rendering them a trusted choice for various industries.APV heat exchangers incorporate innovative design features and cutting-edge technology to enhance heat transfer efficiency, whilst also maintaining a focus on efficiency, as APV heat exchangers contribute to energy savings, reducing operational costs and environmental impact.

7 series from 2 manufacturers

REPAIR OF PLATE HEAT EXCHANGERS

See how you can extend the operating life of your plate heat exchangers and how our Service & Repair strategy aligns with circular economy principles.

TO THE STORY